Standard Bucket for Excavator 1-30 ton

Excavator GD Bucket

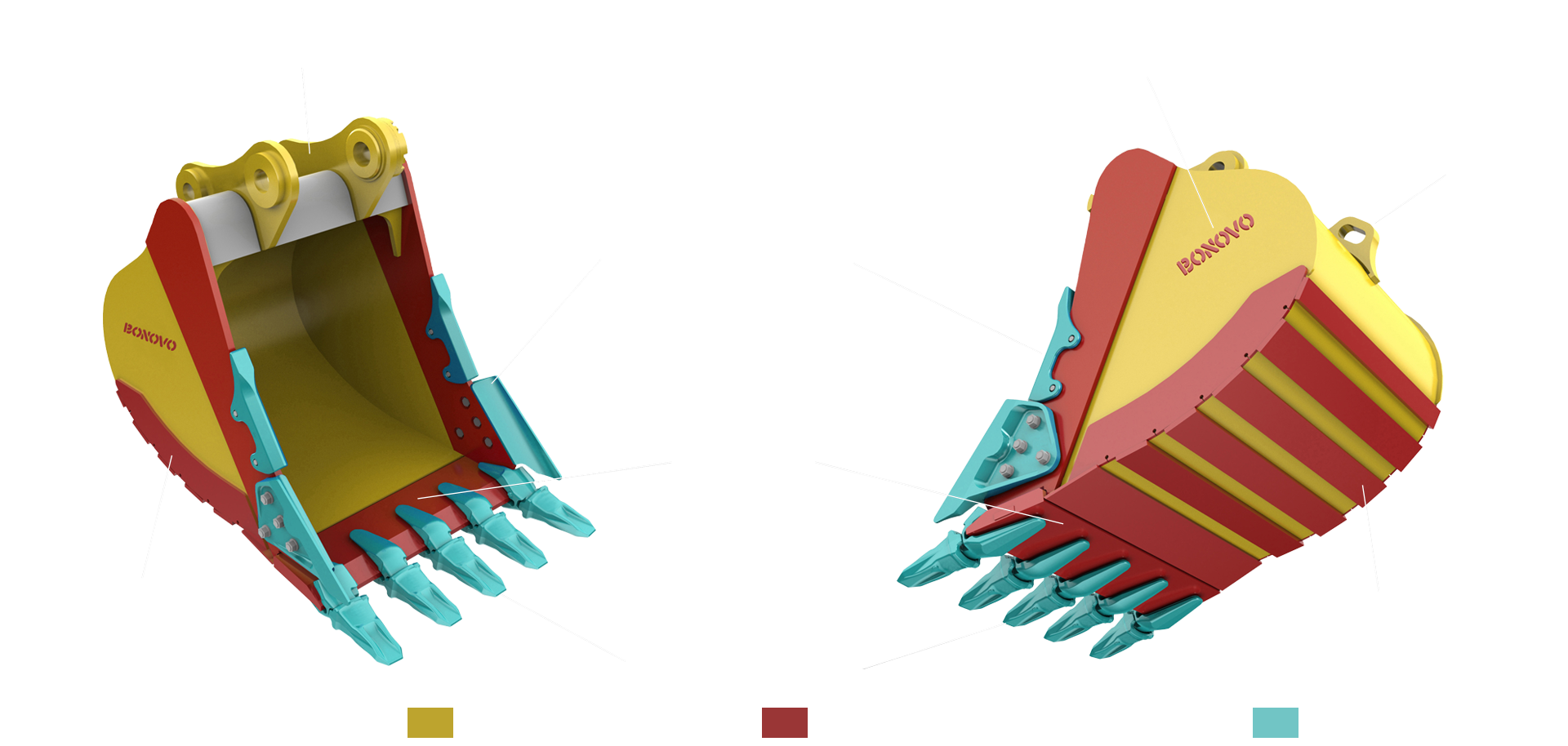

This BONOVO excavator standard buckets are designed for light duty operations such as digging and loading or earth-moving such as earth, sand, loose rock and gravel. Large capacity, high-strength structural steel and advanced bucket adapters save your operations time and increase productivity. BONOVO excavator standard bucket with optional bolt-on rims that perfectly match various brands of excavators and backhoe loaders from 1 to 30 tons.

In order to achieve a more perfect flt, bonovo can customlze the size according to the needs of customers.

1-30 Tons

MATERIAL

HARDOX450,NM400,Q355

WORKING CONDITIONS

Use in light duty operations like excavation and loadingof earth,sand,loose rock and gravel,etc

Capacity

0.5-3CBM

Standard buckets for excavators and backhoe digging buckets are BONOVO's specialties, crafted with extensive production experience and outstanding technical expertise. As a leading manufacturer, we are committed to delivering high-quality, durable bucket products that cater to the ever-changing demands of our customers. We pay meticulous attention to detail and constantly innovate to ensure our buckets provide exceptional performance and reliability. Our standard buckets for excavators and backhoe digging buckets are widely utilized in construction, road building, maintenance, and various other fields, earning widespread acclaim from customers.

For top-quality standard buckets for excavators and backhoe digging buckets, trust BONOVO to meet your construction needs.

BONOVO's Excavator Standard Bucket

This is our basic series, commonly referred to as the standard bucket for excavator. This bucket is ideal for general excavation tasks involving clay, loose soil, sand, and gravel. It is also well-suited for light operating environments where material loading is required. The standard bucket for excavator features side teeth and flat bucket teeth as standard components, enhancing its versatility and performance in various digging and loading applications.

Specification

| Tonnes | Bucket Type | Width | G.E.T | Teeth | Bucket Pins | Weight |

| 2T | GP Digging Bucket | 18''-457mm | J200 series | 4pcs | Included | 90KG |

| 5T | GP Digging Bucket | 24''-610mm | J200 series | 5pcs | Included | 160KG |

| 8T | GP Digging Bucket | 30''-762mm | J220 series | 5pcs | Included | 260KG |

| 12T | GP Digging Bucket | 36''-915mm | J250 series | 5pcs | Included | 405KG |

| 15T | GP Digging Bucket | 42''-1067mm | J250 series | 6pcs | Included | 570KG |

| 20T | GP Digging Bucket | 48''-1220mm | J350 series | 6pcs | Included | 910KG |

| 25T | GP Digging Bucket | 48''-1220mm | J400 series | 6pcs | Included | 1130KG |

| 30T | GP Digging Bucket | 54''-1372mm | J450 series | 5pcs | Included | 1395KG |

Details of our specifications

Bucket Ear

The standard bucket for excavator features a robust design with multi-layer welding beads at the bucket ear positions. This approach ensures the overall structural strength of the standard bucket for excavator, minimizes heat input, reduces deformation, and lowers the likelihood of defects. Additionally, the backhoe digging bucket utilizes an integral boring process for the bushing, which guarantees the concentricity of the bucket ear sleeve and enhances precision.

By focusing on these design elements, both the standard bucket for excavator and the backhoe digging bucket are engineered to offer superior durability and accuracy in various digging applications.

Tooth Adapter

When welding the tooth adapter for a standard bucket for excavator, it is crucial to first heat the adapter to around 200 degrees Celsius. This preheating process helps in achieving a strong weld. The side teeth on both ends of the bucket are welded to the side knife, and the welding bead is extended all the way to the connection with the main cutter and the arc plate. This comprehensive welding approach ensures the overall structural integrity of the main cutter in the bucket body. Consequently, the backhoe digging bucket becomes significantly more robust, especially at the bucket teeth, which are critical during heavy-duty excavation work.

Painting

When selecting a standard bucket for excavator or a backhoe digging bucket, customization and quality are key considerations. Our products offer the flexibility to choose different colors to match various machines, ensuring a perfect fit for your equipment. Before applying the paint, each bucket undergoes a meticulous sand blasting process to prepare the surface, enhancing the final appearance. To ensure long-lasting color and durability, a two-coat painting process is employed, providing a vibrant and durable finish.

For those looking for a standard bucket for excavator or a backhoe digging bucket, our products not only meet functional needs but also offer aesthetic customization, ensuring that your equipment stands out on the job site.