Lebili la Compactor bakeng sa Excavator

mabili a compactor a excavator ke li-attachments tsa excavator tse ka nkang sebaka sa compactor e sisinyehang bakeng sa mesebetsi ea compaction.E na le sebopeho se bonolo ho feta compactor e sisinyehang, e na le moruo, e tšoarella, 'me e na le sekhahla se tlase sa ho hloleha.Ke sesebelisoa sa compaction se nang le lisebelisoa tsa pele tsa mochini.

Lebili la compaction la Bonovo le na le mabili a mararo a arohaneng a nang le mapheo a cheselitsoeng ho isa selikalikoe sa lebili le leng le le leng.Tsena li ts'oaroa ke li-axle tse tloaelehileng 'me li-axle hanger tsa excavator li kenngoa ho li-brackets tse pakeng tsa mabili a behiloeng ho li-axle.Sena se bolela hore lebili la compaction le boima haholo 'me le kenya letsoho ts'ebetsong ea ho kopanya e fokotsang matla a hlokahalang ho tloha ho excavator ho kopanya sebaka, ho phethela mosebetsi ka litsela tse fokolang.Tšebelisano e potlakileng ha e boloke nako feela, litšenyehelo tsa opareitara le khatello ea maikutlo mochining, empa hape e fokotsa litšenyehelo tsa tšebeliso ea mafura le tlhokomelo.

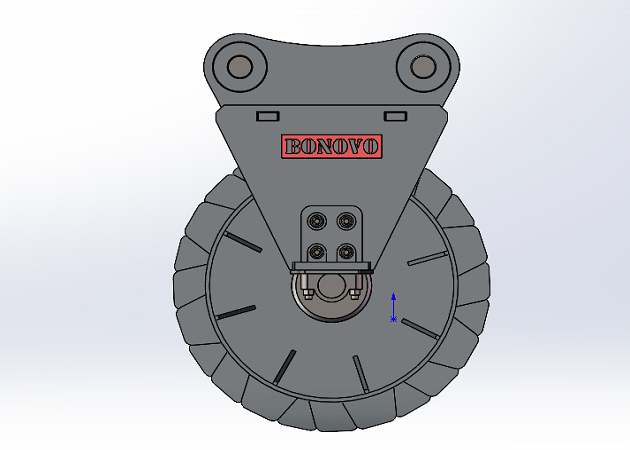

Lebili la compactor ea excavator ke sehokelo sa excavator se sebelisetsoang ho kopanya lisebelisoa tse hlephileng joalo ka mobu, lehlabathe le lehlohlojane.Hangata e kenngoa lipineng tsa excavator kapa mabili.Lebili la compaction la excavator le na le 'mele oa lebili, libere le meno a kopaneng.Nakong ea ts'ebetso, meno a compaction a pshatla mobu, lehlabathe le lehlohlojane ho etsa hore li teteane.

Mabili a compaction a excavator a loketse ho sebelisoa mobung o fapaneng le linthong tse hlephileng, joalo ka bokamorao, lehlabathe, letsopa le lehlohlojane.Melemo ea eona e kenyelletsa:

compaction e sebetsang:Lebili la compaction la excavator le na le matla a maholo a ho kopanya 'me le ka kopanya ka potlako mobu o fapaneng le lisebelisoa tse hlephileng ho ntlafatsa ts'ebetso e sebetsang hantle.

Ho ikamahanya le maemo ho matla:Lebili la compaction la excavator le ka kenngoa litseleng kapa mabiling a excavator, 'me le loketse libaka tse sa tšoaneng le maemo a kaho.

Lisebelisoa tse ngata:Lebili la compaction la excavator le ka sebelisoa eseng feela bakeng sa ho tiisa mobu, empa hape le bakeng sa ho hatella le ho pshatla majoe, makala le lisebelisoa tse ling.

Ho bonolo ho sebetsa:Lebili la compaction la excavator le bonolo ho sebetsa, 'me lebelo la compaction le matla a ho kopanya li ka fetoloa ka ho laola throttle ea excavator le lever ea ho sebetsa.

Hangata mabili a compaction a excavator a entsoe ka lisebelisoa tse matla haholo, tse kang tšepe e matla le lisebelisoa tse sa tsitsang, ho netefatsa hore li tšoarella le ho tšepahala.Nakong ea ts'ebeliso, o hloka ho ela hloko ho boloka 'mele oa lebili o hloekile ebile o tlotsitsoe,' me kamehla hlahloba le ho boloka likarolo tse kang li-bearings le meno a compaction ho netefatsa ts'ebetso ea eona e tloaelehileng le ho lelefatsa bophelo ba ts'ebeletso.

E le ho fihlela sefofane se phethahetseng haholoanyane, bonovo e ka etsa boholo ba eona ho latela litlhoko tsa bareki.

1-40 Ton

TŠEBELETSO

NM400

MOSEBETSI MAEMO

kopanya mekhahlelo e fapaneng ea mobu le lehlohlojane, lehlohlojane le lisebelisoa tse ling tsa ho tlatsa

Lebili la Compaction

Tlhaloso

| Tonnage | boima/kg | Bophara ba lebili A/mm | Bophara ba lebili B/mm | Boholo ba bophara ba ho sebetsa C/mm | Roller ea mohlala D |

| 1-2T | 115 | 450 | 380 | 470 | PC100 |

| 3-4T | 260 | 450 | 380 | 470 | PC100 |

| 5-6T | 290 | 450 | 450 | 540 | PC120 |

| 7-8T | 320 | 450 | 500 | 600 | PC200 |

| 11-18T | 620 | 500 | 600 | 770 | PC200 |

| 20-29T | 950 | 600 | 890 | 1070 | PC300 |

| 30-39T | 1080 | 650 | 920 | 1090 | PC400 |

Lebili la Compaction ke sehokelo sa excavator se ka nkang sebaka sa compactor e sisinyehang bakeng sa mesebetsi ea compaction.E na le sebopeho se bonolo ho feta compactor e sisinyehang, e na le moruo, e tšoarella, 'me e na le sekhahla se tlase sa ho hloleha.Ke sesebelisoa sa compaction se nang le lisebelisoa tsa pele tsa mochini.

Lebili la compaction le bonolo ho le kenya ebile le bonolo ho le sebelisa, 'me le khona ho kopanya likarolo tse fapaneng tsa mobu le lehlohlojane, lehlohlojane le lisebelisoa tse ling tsa ho tlatsa.E loketse ka ho khetheha bakeng sa libaka tsa kaho tse batlang li le moqotetsane tse ke keng tsa finyelloa ke mechine e meholo ea compaction.Hangata e sebelisoa bakeng sa ho kopanya mobu o ka tlaase oa bethe ea litsela kapa mobu oa mokokotlo oa mokoti.Ha lebili la compactor le kopanya karolo e ka tlase ea bethe ea litsela kapa sekoti sa motheo, letsoho la Excavator ke mohloli o ka sehloohong oa matla a ho etsa ts'ebetso ea compaction.

Lebili la compaction la Bonovo le na le mabili a mararo a arohaneng a nang le mapheo a cheselitsoeng ho isa selikalikoe sa lebili le leng le le leng.Tsena li ts'oaroa ke li-axle tse tloaelehileng 'me li-axle hanger tsa excavator li kenngoa ho li-brackets tse pakeng tsa mabili a behiloeng ho li-axle.Sena se bolela hore lebili la compaction le boima haholo 'me le kenya letsoho ts'ebetsong ea ho kopanya e fokotsang matla a hlokahalang ho tloha ho excavator ho kopanya sebaka, ho phethela mosebetsi ka litsela tse fokolang.Tšebelisano e potlakileng ha e boloke nako feela, litšenyehelo tsa opareitara le khatello ea maikutlo mochining, empa hape e fokotsa litšenyehelo tsa tšebeliso ea mafura le tlhokomelo.

Lebili la compaction le entsoe haholo ka: ear plate, foreimi ea lebili, 'mele oa lebili le thipa ea lebili.

Lintlha tsa lintlha tsa rona

Rolara

Sebelisa lirolara sebakeng sa libering ho potoloha 'mele oa lebili.Li-roller ha li hloke tlhokomelo 'me li na le bophelo bo bolelele ba tšebeletso ho feta li-bearings.Boholo ba rolara bo etsa qeto ea hore bophara ba lebili la compactor bo ke ke ba ba boholo haholo.

'mele oa lebili

'Mele oa lebili la lebili la compaction o sekoti o etselitsoe ho fokotsa boima ba sehlahisoa.

'Mele oa lebili o entsoe ka lipoleiti tse peli tsa tšepe tse chitja le poleiti e phuthoang ka har'a poleiti e chitja ea arc e cheselitsoeng lebiling le tšehetsang.Likhopo tse khutlo-tharo li cheselitsoe pakeng tsa poleiti e chitja le poleiti ea arc ho matlafatsa 'mele oa lebili.

mokoloko oa lebili

Lebili la lebili le entsoe ka tšepe ea tšepe, e nang le molemo oa ho ba matla le ho se sebetse, empa bothata ke hore bo boima 'me boima bohle ba sehlahisoa bo boima.Ho e-na le hoo, ho ka sebelisoa li-castings tse se nang letho.Ho hlophisoa ha li-wheel block ho ka etsoa ho latela litlhoko tsa bareki.