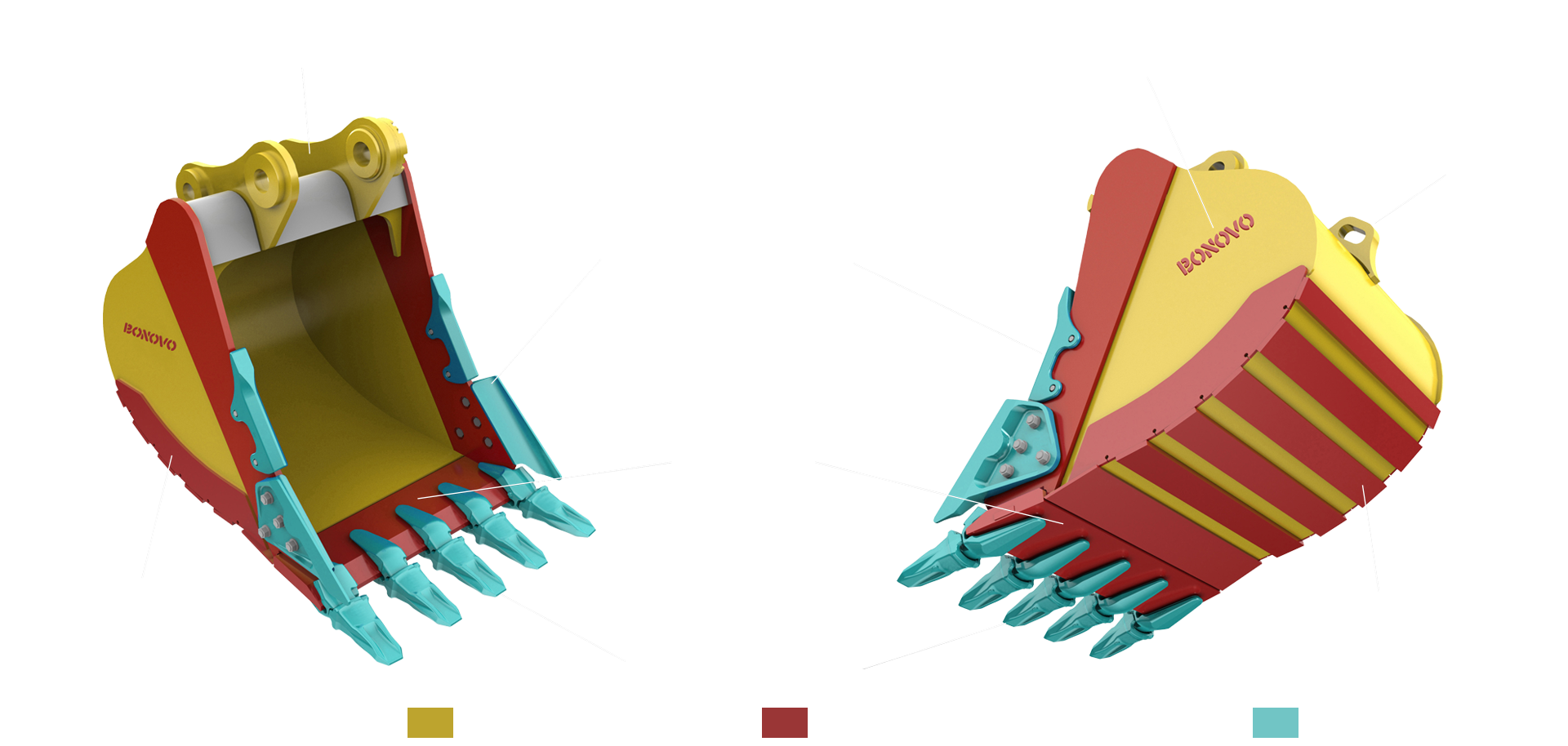

skeleton bucket sieve bucket factory

Skeleton Bucket is the Removal of Rock and Debris without the Soil. Other Applications Include the Sorting Rocks of a Specific Size from Piles.

Skeleton Bucket application

Our Skeleton Buckets are Designed to Attack all Varieties of Applications from Demolition to Standard Stock Piles. The Skeletal Design is Set to Cater for Smaller as well as Larger Objects to Achieve Your Goals.

In order to achieve a more perfect flt, bonovo can customlze the size according to the needs of customers.

1-50 Ton

MATERIAL

HARDOX450.NM400,Q355

WORKING CONDITIONS

applied to excavation of relatively loose materials in governmental, agricutural, forestry, water conservancy projects.

Screen Spacing

60-120MM

The Primary Function of a Skeleton Bucket is the Removal of Rock and Debris without the Soil. Other Applications Include the Sorting Rocks of a Specific Size from Piles. Our sieve Buckets are Designed to Attack all Varieties of Applications from Demolition to Standard Stock Piles. The Skeletal Design is Set to Cater for Smaller as well as Larger Objects to Achieve Your Goals.

Specification

| Tonnes | Width/mm | G.E.T | Teeth | Screen Spacing/mm | Bucket Pins | Weight/KG |

| 2T | 24''-610mm | J200 series | 5pcs | 70*70 | Included | 90 |

| 5T | 30''-762mm | J200 series | 5pcs | 70*70 | Included | 180 |

| 8T | 30''-762mm | J220 series | 5pcs | 80*80 | Included | 250 |

| 12T | 36''-915mm | J250 series | 5pcs | 80*80 | Included | 390 |

| 15T | 42''-1067mm | J250 series | 6pcs | 90*90 | Included | 590 |

| 20T | 48''-1220mm | J350 series | 6pcs | 90*90 | Included | 900 |

| 25T | 48''-1220mm | J400 series | 6pcs | 100*100 | Included | 1160 |

| 30T | 54''-1372mm | J450 series | 5pcs | 100*100 | Included | 1390 |

Details of our specifications

Bucket Ear

The position of the bucket ear adopts multi-layer welding bead to ensure the overall strength of the structure, reduce the amount of heat input, reduce the deformation, reduce the probability of defects, and the bushing adopts the integral boring process to ensure the concentricity of the bucket ear sleeve and higher precision.

Tooth Adapter

The tooth adapter welding is first hotter about 200 degrees before welding, the side teeth on both sides are welded with the side knife, and the welding bead is extended to the connection with the main cutter and the arc plate, which ensures the overall strength of the main cutter of the bucket body, and the bucket teeth on both sides are stronger during the working process.

Screen Mesh

Full welding is used between the round steel and the fence strip of the skeleton bucket, and the overall strength of the grille strip is better, and the round steel will not loosen and crack after working for a long time. Extended service life.