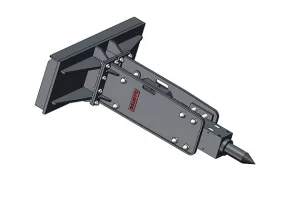

Side Excavator Hammer

Side Type Excavator Hammer

The side hydraulic hammer is mainly used to sharpen and break materials when the crushing object is relatively narrow. Utilizing the characteristic of the cone shape of the hammer head, it produces a cutting effect, allowing the broken material to split along the cone surface to achieve the purpose of crushing.Triangle hydraulic hammer is normally used on excavator or backhoe loader.

Kinds of Chisels For Excavator Hammer:Moil point,Blunt tool,Flat chisel,Conical point

Side Type Excavator Hammer Video

In order to achieve a more perfect flt, bonovo can customlze the size according to the needs of customers.

1-55T

MATERIAL

20Crmo

WORKING CONDITIONS

Demolition, Construction, Quarry and Production Breaking Needs

Side Type

Excavator hammer, also known as hydraulic breaker also known as hydraulic breaker hammer, this machine is powered by hydrostatic pressure, driving the piston to reciprocate, and the piston strokes at high speed Impact the drill rod, and the drill rod breaks solids such as ore and concrete.

Excavator hammers are widely used in gravel, mines, roads, civil engineering, demolition engineering, metallurgy and tunnel engineering and other fields. It can be divided into triangular breaker, vertical breaker, silent breaker and slip breaker (special for skid loader)

Side Type Hydraulic Hammer

The side hydraulic hammer is mainly used to sharpen and break materials when the crushing object is relatively narrow. Utilizing the characteristic of the cone shape of the hammer head, it produces a cutting effect, allowing the broken material to split along the cone surface to achieve the purpose of crushing.Triangle hydraulic hammer is normally used on excavator or backhoe loader.

Kinds of Chisels For Excavator Hammer:Moil point,Blunt tool,Flat chisel,Conical point

Specification

| Model | HB450 | HB530 | HB680 | HB750 | HB850 | HB1000 | HB1250 | HB1400 | HB1500 | HB1650 | HB1750 |

| Tone | 1-1.5T | 2.5-4.5T | 3-7T | 6-9T | 7-14T | 10-15T | 15-25 | 20-30 | 25-30 | 30-45T | 40-55T |

| Side Type Weight(kg) | 100 | 130 | 250 | 380 | 510 | 760 | 1320 | 1700 | 2420 | 2900 | 3750 |

| Top Type Weight(kg) | 122 | 150 | 300 | 430 | 550 | 820 | 1380 | 1740 | 2500 | 3100 | 3970 |

| Silcenced Type Weight(kg) | 150 | 190 | 340 | 480 | 580 | 950 | 1450 | 1850 | 2600 | 3150 | 4150 |

| Skid Steer Weight(kg) | 270 | 350 | 500 | 650 | |||||||

| Working Oil Flow (L/min) |

20-30 | 25-45 | 36-60 | 50-90 | 45-85 | 80-120 | 90-120 | 150-190 | 150-230 | 200-260 | 200-280 |

| Working Pressure (kg/cm2) |

90-100 | 90-120 | 110-140 | 120-170 | 127-147 | 150-170 | 150-170 | 165-185 | 170-190 | 180-200 | 180-200 |

| Impact Rate (b.p.m) |

500-1000 | 500-1000 | 500-900 | 400-800 | 400-800 | 400-700 | 400-650 | 400-500 | 300-450 | 250-400 | 250-350 |

| Chicel Diameter (mm) |

45 | 53 | 68 | 75 | 85 | 100 | 125 | 140 | 150 | 165 | 175 |

Details of our specifications

The movement is divided into cylinder, middle cylinder and front bar. The material of the cylinder is made of 20Crmo. 20Crmo is a kind of steel, which belongs to alloy structural steel. It is a low alloy high strength steel with good cold extrusion and cold stamping performance , good weldability and machinability. The Mo element of 20CrMo has good thermal stability. The components of the breaker movement generate a lot of heat in the working state. The Mo element can ensure the stability of the material and reduce the decline in mechanical properties.

The material of the chisel is divided into 45# 40CR 42CR. Our products are all made of 42Cr material. This material has the characteristics of high compressive strength, high cutting performance, good flexibility, small deformation during heat treatment, strong creep strength at continuous high temperature, and durable strength. Longer service life

Export wooden box packaging reduce the damage of sea moisture to the product, and the equipment of common tools can facilitate the routine maintenance of customers.