Reasonable price Bomag Plate Compactor – BONOVO Excavator Rotating Hydraulic Demotion Grapple – Bonovo

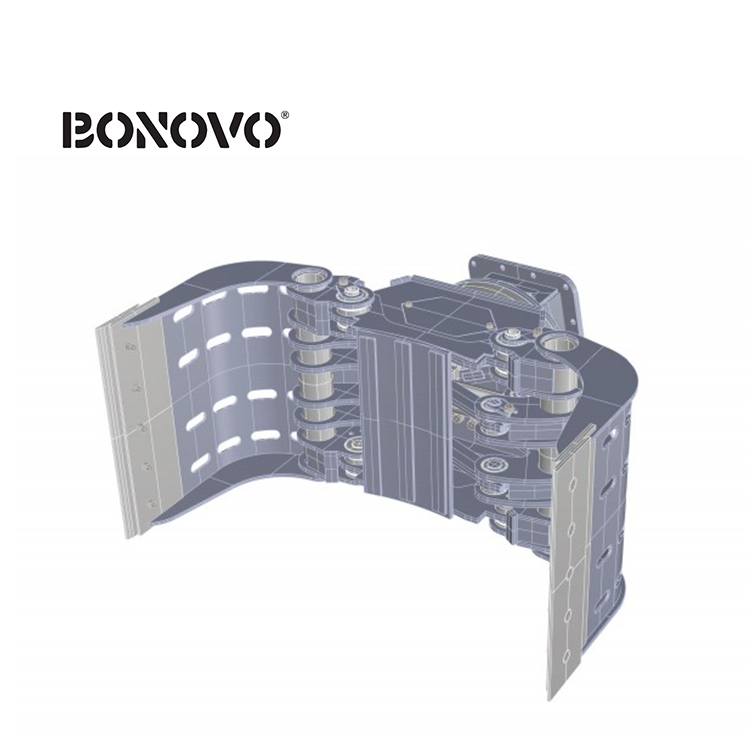

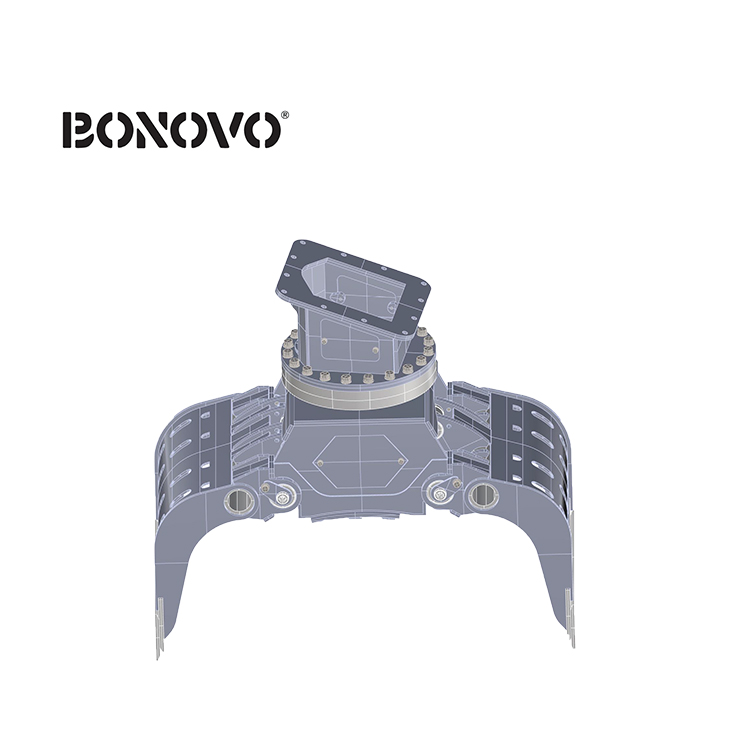

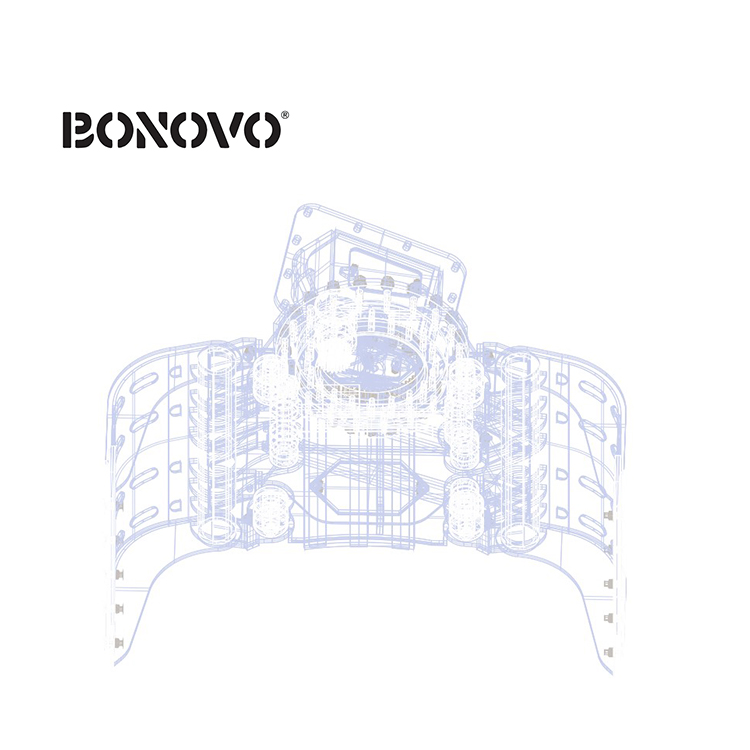

The demolition grapples also known as “iron claw”, can be divided into mechanical grapples, which grab with the most power, while hydraulic grapples offer a full 360 degrees of mobility and work with higher precision. Bonovo rotating grapples are optimized for demolition, rock and waste handling applications. Our strong 360° hydraulic motor rotating system and high-tensile steel result in greater productivity and lower operating costs.

- 360 degree hydraulic rotation makes it a more flexible grappling effect

- Simple structure, lightweight and high grasping force

- The built-in balancing valve of the oil cylinder makes the operation smooth and maintains clamping force

- Built with wear-proof steel to last longer and go an extra step toward maximum durability.

Raw materials: Many types of steel plates are available :Q345,NM400,HARDOX,etc The material will be quality-inspected when they are delivered to the workshop.

Cutting: We have two kinds of cutting machine:numerical control cutting machine and numerical plasma control cutting machine.The former is used to cut steel plates with a thickness of more than 20mm, and the latter is used to cut steel plates with a thickness of less than 20mm.

They cut the entire steel plates into each part of bucket according to drawings,then the parts will be polished and sent to machining area.

Machining Area:

1.Drilling

-Mainly drill the holes in bushing and side cutting edge.

2.Boring

-Accurate inner diameter of bushing to make sure the pins match the bushing perfectly.

3.Turning

-Processing bushing

4.Milling

-Processing flange plate (CAT and Komatsu excavator over 20 ton bucket will use flange plate).

5.Beveling

-Make groove at steel plate to increase the welding area and make sure more solid welding.

6.Pressure Bending

-Bend thick steel plate ,especially the part of ear bracket.

7.Rolling

-Roll the steel plate to arc shape.

-Make groove at steel plate to increase the welding area and make sure more solid welding.

Welding Area-The most remarkable of our advantage

-Bonovo uses carbon dioxide gas shielded welding machine and flux-cored wire ,which is adapted to any position in space . Multi-pass welding and multi-layer welding are all our feature.

-Adapter and blade edge are both through preheated before welding. The temperature is controlled reasonably between 120-150℃

-The welding voltage is maintained at 270-290 volts , and the current is maintained at 28-30 amps to ensure the stability of welding process

-Experienced welders are technically skilled with double hands , which makes the weld seam achieve graceful fish-scale shape

Shot blasting advantages:

1.Remove the surface oxide layer of the product

2.Releasing the welding hard force generated during welding

3.Increase the paint's adhesion and make the paint more firmly absorbed on the steel plate.

Inspection

From raw materials to finished products, the whole process is under strict quality inspection included flaw detection,weld inspection,structure size inspection,surface inspection,painting inspection,assembly inspection,package inspection etc.to keep our quality standard,