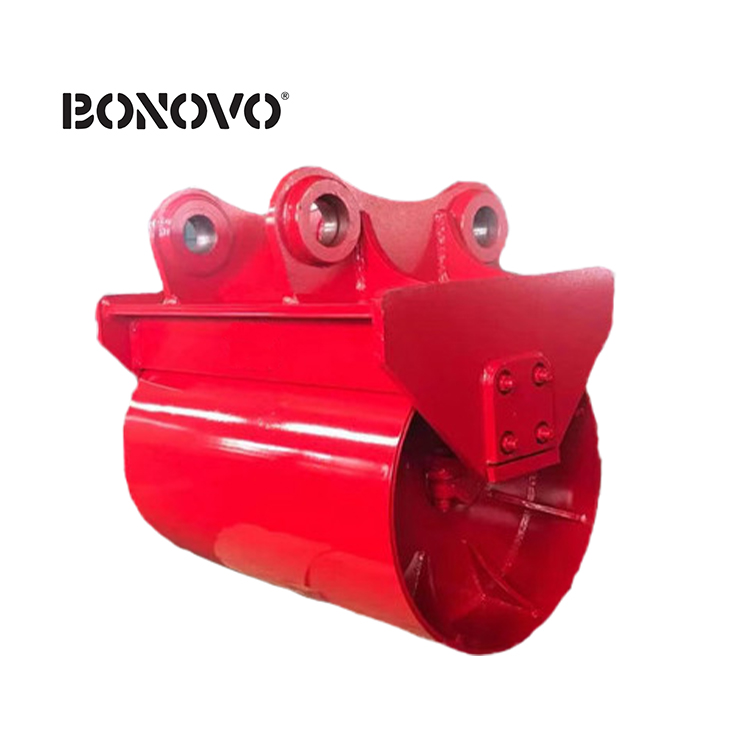

Bonovo Compaction Wheels are designed to deliver optimal performance through quicker compaction – more particularly in trenches. They deliver exceptional compaction on the toughest terrains, under the harshest conditions, while lasting longer, using less fuel and minimising operational costs.

Bonovo Compaction Wheels are designed to reinstate material to its original condition after remedial work has been carried out or pipes have been laid. Apart from different designs of wheels for various applications, there are some interesting designs of pads, some efficient, and some unfortunate. The ideal design are pads that are tapered from the flat surface to the back where they are welded to the wheel or roller so that they do not “lift” the compacted material as they roll over the surface.

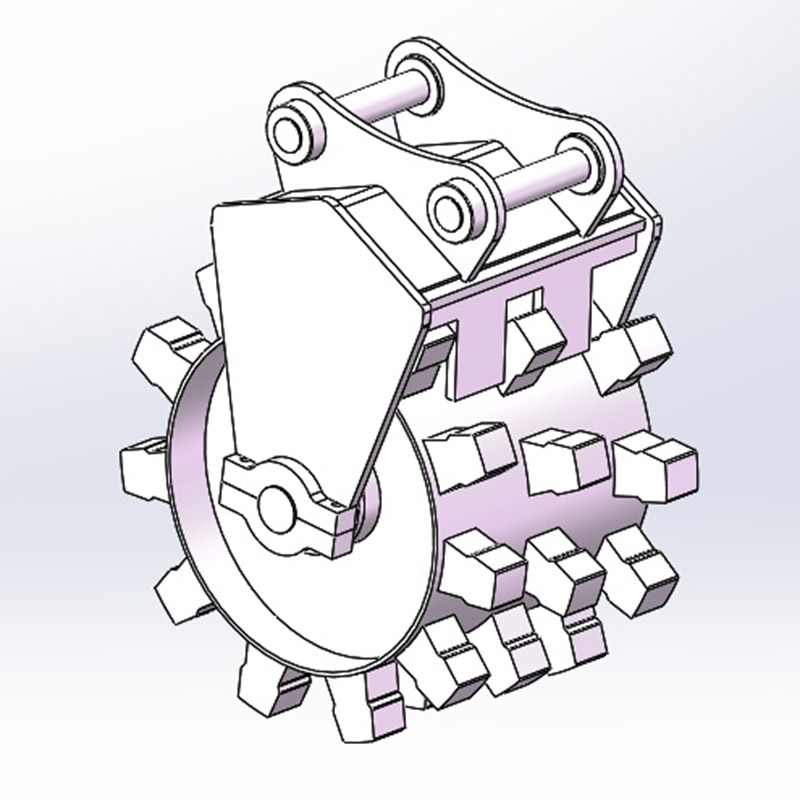

The Bonovo compaction wheel has three separate wheels with pads welded to the circumference of each wheel. These are held in place by a common axle and the excavator hanger brackets are fixed to bushed brackets between the wheels set to the axles. This means the compaction wheel is quite heavy and contributes to the compaction process which reduces the power needed from the excavator to compact the terrain, completing the job with less passes. Quicker compaction not only saves time, operator costs and stress on the machine, but also reduces fuel consumption and maintenance costs.

Inspection

Since 2006 the scope of our services are to provide you and your team with the most complete product lines of attachment and walk chassis for construction equipment. they designed to execute your toughest digging and loading jobs fast. We've made it a focal point to make sure every product goes through strict quality tests so you can avoid delays and get the maximum value from your equipment.