Line Boring Machine 60mm

Delivery conditions: FOB Shanghai

Production time: based on your QTY

Warranty: 12 Months

In order to achieve a more perfect fit, Bonovo can customize the size according to the needs of customers.

Portable Boring Machine 60mm

Harness the power of our Line Boring Equipment with the portable Line Bore Machine, ideal for on-site maintenance of construction machinery. This precision tool excels in processing small pipe inner holes and concentric spacing holes, ensuring smooth operations. Widely applicable to excavators, cranes, and loaders, it slashes equipment maintenance costs and boosts efficiency. Post-repair welding or hole sleeving, the Line Bore Machine effortlessly machines revolving, articulated, and shaft pin holes on various engineering machinery structures. Its one-time positioning processing guarantees coaxiality for porous components in excavators, loaders, presses, and cranes.

| Model | BM-40 | BM-50 | BWM-50S | BWM-50P | BM-60 | BM-60S |

| Main motor | 1.5KW brushless DC motor | 1.5KW brushless DC motor | 3KW vertical servo motor | 3KW servo motor | 2KW DC servo motor | 2KW DC servo motor |

| Tool feed motor power | 120W | |||||

| Main motor output speed | 125 rpm | 125 rpm | 0-300 rpm | 0-300 rpm | 100 rpm | 80 rpm |

| Motor speed regulation | Infinitely variable speed | Continuously variable speed can realize forward and reverse rotation | ||||

| Feeding method | Hand-in-hand | |||||

| Boring bar diameter | 40mm | 50mm | 50mm | 50mm | 60mm | 60mm |

| Boring range | 45-200mm | 55mm-260mm | 55mm-260mm | 55mm-260mm | 65--500mm | 65-500mm |

| Feed stroke | 380mm | 380mm | 200mm | 200mm | 420mm | 740mm |

| Maximum number of cuts on one side | 2-3mm | 2-3mm | 3mm | 2mm | 2-3mm | 2-3mm |

| Processing roundness | 0.03mm | 0.03mm | 0.02mm | 0.03mm | 0.03mm | 0.05mm |

| Roughness | 3.2um | 3.2 | 3.2 | 3.2 | 3.2um | 3.2um |

| Installation method | Welding fixation | Welding fixation | Welding fixation | Welding fixation | welding | welding |

| Welding hole range | * | * | 55-230mm | 55-230mm | * | * |

| Single side welding thickness | * | * | 3-4mm | 2-3mm | * | * |

| Welding wire model | * | * | 1.0 | 1.0 | * | * |

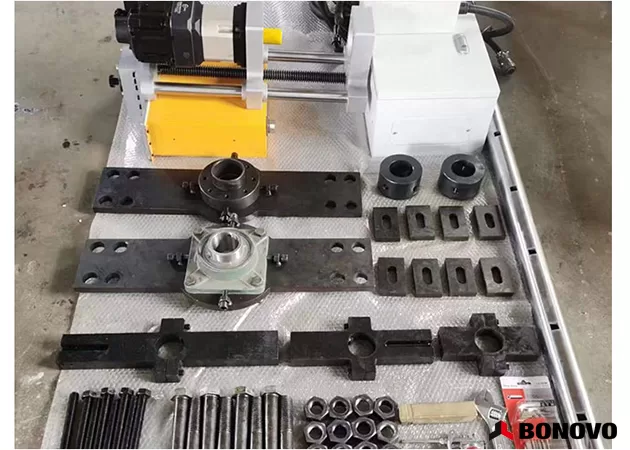

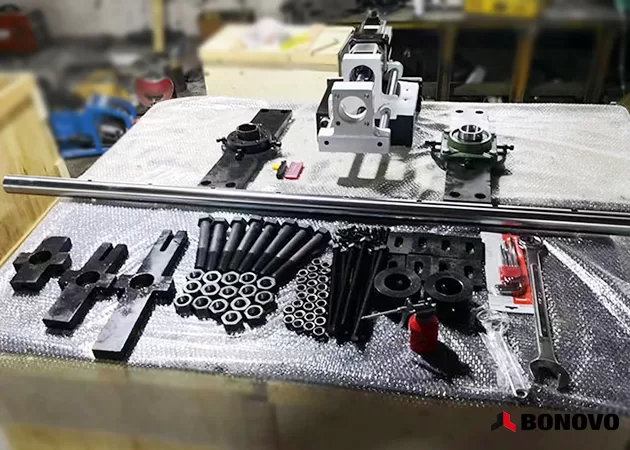

| Matching accessories | boring bar 1.5m long: 1 tool holder: 1 top plate: 1 clip blades: 1 box tool handle: 1 centering sleeves: 4 (2 large and 2 small) support seats: 2 a set of tools | boring bar 1.5m long: 1 tool holder: 1 top plate: 1 machine clamp blades: 1 box tool handles: 2 top tool sleeve: 1 centering taper sleeves (two large and two small): 4 support seats: 2 support bolts: 8 a set of tools | Machine head: 1 set, boring bar diameter 50mm, tool bar 1.5m long: 1 tool bar long 600: 1 support seat: 2 tiles support: 1 lock buckle: 1 support bolt: 8 centering sleeves: 4 tool holder: 1 top plate: 1 oil can: 1 trap: 1 hexagonal wrench: 1 clamp blades: 1 box (10 pieces), machine clamp handle: (16*16 handle one Root, one 12*12 tool handle) top tool sheath: 1 spare small screw: 1 pack of wire feed hose: 2 main welding machine connection cables: 1 1.2m long welding gun rod: 1 30cm long welding gun rod : 1 centering sleeve: 1 protective cover: 3 contact tips: 3 | CNC display screen: 1 machine head: 1 unit, boring bar diameter 50mm tool bar 1.5m long: 1 tool bar long 600: 1 support seat: 2 support tile frame: 1 lock buckle: 1 support bolt: 8 centering sleeve: 4 tool holders: 1 top plate: 1 oil can: 1 trap: 1 hexagonal wrench: 1 set of machine clamp blades: 1 box (10 pieces), machine clamp tool handle: ( One 16*16 tool handle, one 12*12 tool handle) top tool holder: 1 spare small screw: 1 pack wire feed hose: 2 main welding machine connection cable: 1 1.2m long welding gun rod: 1 30 cm long welding gun rod: 1 centering sleeve: 1 protective cover: 3 contact tips: 3 | machine head: 1 tool bar 2m long: 1 support seats: 2 centering device: 1 tool holders of different specifications: 3 support bolts: 8 blades: 1 box tool handle: 1 oil pot: 1 flexible A wrench: 1 hexagonal wrenches: 1 | spindle box: 1 tool feed box: 1 electric motor: 1 boring bar 2m long: 1 3 types of auxiliary tool holders (choose different specifications of tool holders according to the size of the machining hole), machine clamp blades: 1 box machine A knife handle: 1 a complete set of tools, supporting seats: 1 centering devices: 1 set screw rod: 1 |