Products

BONOVO, a trusted attachments maker since 1998, partners with global dealers. Its robust R&D & sales teams deliver customized solutions with superior quality, winning market trust. Specializes in excavator & skid steer attachments like buckets, grapples, augers, hammers, quick couplers, rippers, rakes, forks, and other attachments.

-

Product name : smooth drum compaction wheel

Suitable Excavator(ton): 1-60T

Core Components : steel

-

Undercarriage Parts Front Idlers for Excavator Tracks

The front idler wheel of the excavator track chassis component is one of the important parts of the excavator. Its function is to support and transmit the load and help control the tension of the track. The front idler is usually installed at the front of the excavator track system and works together with other components such as track chains, sprockets, and travel motors to jointly realize the walking, steering, and braking functions of the excavator.

During the operation of the excavator, the front idler wheel needs to bear the weight from the crawler chain and traveling motor, as well as the reaction force from the ground and the excavator. Therefore, the front idler wheel needs to have high load-bearing capacity and durability to ensure the normal and stable operation of the excavator.

In order to improve the durability and service life of the front idler, high-strength materials and advanced manufacturing processes are usually used. In addition, during installation and use, attention needs to be paid to adjusting the track tension, and regular inspection and maintenance of the front idler wheel and its surrounding components to ensure its normal operation and extend its service life.

BONOVO——Excellent quality, the choice of excavators

BONOVO has won the trust of users around the world with its excellent quality and performance. Our front idler pulley is made of high-quality materials and advanced manufacturing processes, with high load-bearing capacity and durability, ensuring the normal and stable operation of the excavator.

Choose BONOVO and you will get:

High-quality products: We strictly control product quality to ensure that every product meets the highest standards.

Reliable after-sales service: We provide a full range of after-sales services, including technical support, maintenance and spare parts supply, to ensure that your excavator is always in optimal condition.

Reduce operating costs: Our products are efficient and durable, which can reduce your repair and replacement costs and improve operating efficiency.

Improve productivity: Our front idler wheel ensures stable travel, steering and braking of the excavator, thereby improving productivity.When you choose BONOVO, you will get excellent quality and performance to provide strong support for your excavator. Let us create a better future together!

-

1.sprocket is suitable for excavator. Digger, and special machienry.

2.visible casting technology and optimized structure design to reduce stress concentration and preventcasting defective.

3.Independent researched material and special heat treatment to guarantee proper hardness and effective -

They are well suited for the secondary processing of various materials by grabbing and placing, sorting, raking, loading and unloading loose materials including wood, steel, brick, stone and large rocks.

-

Long reach arm and boom for excavator

Bonovo Two Section Long Reach Boom and Arm is the most popular type of Boom and Arm.By Lengthening the boom and arm, it can be used in most long reach work conditions.A two section long reach arm & boom includes:Long boom *1,Long arm *1,bucket *1,bucket cylinder *1,H-Link&I-Link *1 set,pipes&hoses.

-

Hydraulic Thumbs for Excavator 1-40 Tons

If you want to increase the capabilities of your excavator, a quick and easy way is to add a hydraulic excavator thumb. With the BONOVO series attachments, the application scope of the excavator will be further expanded, not only limited to excavation operations, but also material handling can be easily completed. Hydraulic thumbs are especially useful for handling bulky materials that are difficult to handle with a bucket, such as rocks, concrete, tree limbs, and more. With the addition of a hydraulic thumb, the excavator can grab and carry these materials more effectively, greatly improving operating efficiency and saving you valuable time.

-

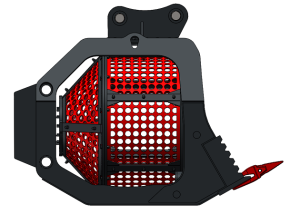

Rotary Screening Bucket For Excavator 1-50 Tons

rotating screening bucket application

BONOVO Rotary Screening Bucket is designed to be tough and increase productivity. The Screening Drum is made of solid steel round tubular tines.The Rotary Screening Bucket function easily sifts out soil and debris, by spinning the Screening Drum. This makes the sifting process faster, easier, and more efficient.They are equipped with interchangeable modular panels to meet any screening requirements for the job.

-

(1) Each roller shell is carefully heat treated to ensure long wear life and stress resistance;

(2) Each roller is precision machined to house special high impact low wear bimetal bushings.

(3) Reliable and long life time guaranteed;

(4) High strength and superior wear resistance. -

Tonnage:1-50Ton

Type:Pin on/Weld on

Size:Customizable

Recommended Applications: used in a variety of applications including the handling of disposable waste, brush, logs, construction debris, stones, pipes, landscape works and many others.

-

Side Type Excavator Hammer

The side hydraulic hammer is mainly used to sharpen and break materials when the crushing object is relatively narrow. Utilizing the characteristic of the cone shape of the hammer head, it produces a cutting effect, allowing the broken material to split along the cone surface to achieve the purpose of crushing.Triangle hydraulic hammer is normally used on excavator or backhoe loader.

Kinds of Chisels For Excavator Hammer:Moil point,Blunt tool,Flat chisel,Conical point

Side Type Excavator Hammer Video

-

Bonovo Equipment Sales | High quality Hydraulic stone grapple for excavators

Suitable Excavator(ton):3-25 ton

Weight:90

- Type:Hydraulic Rotating Grapple

- Application:For waste metals disposal, stones, woods etc.

-

Hydraulic Demotion Rotating Grapples For Excavators 3-25 Tons

Excavator Range:3-25T

Rotation Degree:360°

Max Opening:1045-1880mm

Recommended Applications:Optimized for demolition, rock and waste handling applications

-300x215.jpg)