Top 5 Reasons a Hydraulic Thumb Attachment is a Game-Changer for Your Excavato - Bonovo

This article explains why adding a hydraulic thumb to your excavator is a smart investment. It’s not just an add-on; it's a tool that significantly boosts your machine's capabilities and your overall efficiency on the job site. We'll explore the top 5 reasons why a hydraulic thumb for excavator transforms your excavator attachment usage, bringing enhanced versatility and ultimately, a better return on your investment. Discover why industry professionals are using hydraulic thumbs and how it could be benefitial to your needs. Whether dealing with tough demolition, or percisely picking up debris, hydraulic hoses powered thumb could be what you have been missing.

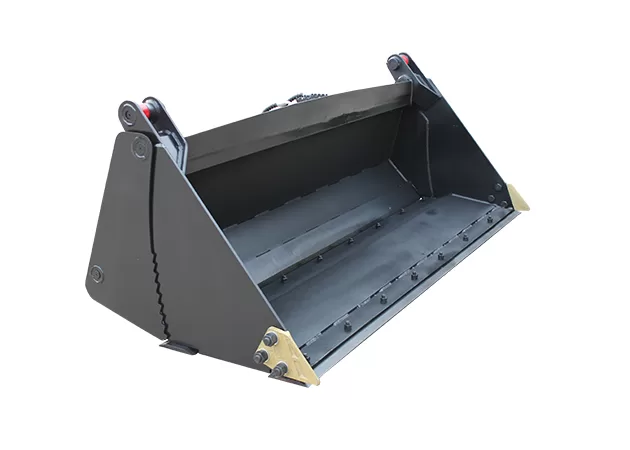

1. What is a Hydraulic Thumb on an Excavator?

A hydraulic thumb is a powerful attachment mounted on the excavator's arm, working in conjunction with the bucket. It essentially acts like a human thumb, providing a strong grip to securely hold materials against the bucket. Unlike a fixed or mechanical thumb, a hydraulic thumb uses hydraulic cylinders to open and close, allowing the operator to adjust the grip pressure and angle from the cabin of the machine.

This ability to dynamically control the thumb attachment dramatically improves the excavator's ability to pick up, hold, and move irregularly shaped objects like rocks, logs, concrete debris, and other materials. It adds a new dimension of precision and control to material handling tasks.

2. What Are The Two Main Types of Excavator Thumbs?

There are fundamentally two types of hydraulic thumbs: Pin-Mounted Thumb and Progressive Link (Stick-Mounted) Thumb. Understanding the difference is crucial for choosing the right one for your needs.

-

Pin-Mounted Thumb: This type rotates on the same pivot point as the bucket pin. It's generally simpler in design and often more cost-effective. The pin-mounted thumb is a good choice for general-purpose applications. This option also provides a good constant gripping ability.

-

Progressive Link (Stick-Mounted) Thumb: This thumb is mounted directly to the excavator stick and uses a linkage system to provide a wider range of motion. The progressive link allows the thumb to retract further and often provides a more consistent grip throughout the bucket's curling motion. This makes them thumbs are ideal for tasks requiring greater precision and flexibility.

3. How Does a Hydraulic Thumb Increase Excavator Versatility?

The core benefit of a hydraulic thumb is its incredible boost to excavator versatility. Without a thumb, an excavator is primarily limited to digging and scooping. Adding a hydraulic thumb for excavator transforms it into a multi-functional tool capable of:

- Precise Material Handling: Securely grasping and moving oddly shaped objects, preventing slippage.

- Land Clearing: Efficiently removing trees, stumps, and brush.

- Demolition: Gripping and tearing down structures, sorting debris.

- Landscaping: Placing rocks, logs, and other landscape features with accuracy.

- Pipe Laying: Holding and positioning pipes securely.

This versatility means fewer machine swaps on the job site, increasing efficiency and reducing downtime.

4. Why is a Hydraulic Thumb Attachment Better Than a Manual Thumb?

While manual thumbs are a cheaper initial investment, hydraulic excavator thumbs offer significant advantages that quickly justify the higher cost:

| Feature | Manual Thumb | Hydraulic Thumb |

|---|---|---|

| Adjustment | Requires manual adjustment outside the cabin | Adjusted from within the cabin of the machine |

| Precision | Limited grip adjustment | Precise and variable grip pressure |

| Operator Fatigue | Higher | Lower |

| Efficiency | Lower | Higher |

| Safety | Lower | Higher |

| Versatility | limited | wide range |

The ability of the operator to adjust the thumb's position and pressure without leaving the cab is a huge safety and productivity boost. The power of a hydraulic system also provides a far stronger and more reliable grip compared to manual options. The hydraulic power also eliminates the strain and effort that would be required to operate a manual system.

5. How Does a Hydraulic Thumb Improve Material Handling?

Material handling is where the hydraulic thumb truly shines. The ability to securely grasp and control materials of varying shapes and sizes is unmatched. Imagine trying to pick up a large, irregularly shaped rock or a pile of broken concrete with just a bucket. It's difficult, inefficient, and potentially dangerous.

A hydraulic thumb provides the clamping force needed to securely hold these objects, preventing them from slipping or rolling out of the bucket. This not only speeds up the loading process but also reduces the risk of dropped materials causing damage or injury. This is crucial for work involving demolition.

6. Can a Hydraulic Thumb Attachment Help with Demolition?

Absolutely! Hydraulic thumbs are invaluable tools in demolition projects. They provide the necessary grip to:

- Tear Down Structures: The thumb and bucket work together to pull down walls, roofs, and other structural elements.

- Sort Debris: Quickly and efficiently separate different types of debris, like concrete, wood, and metal, for recycling or disposal.

- Load Debris: Securely grasp and load large, bulky pieces of debris into trucks or containers.

The precise control offered by hydraulic thumbs is essential for safe and efficient demolition work.

7. What are the Key Features to Look for in a Hydraulic Thumb?

When choosing a hydraulic thumb, consider these key features:

- Compatibility: Ensure the thumb is compatible with your excavator's make and model. Check out BONOVO's range of excavator attachments for compatibility information.

- Construction: Look for heavy-duty construction using high-strength, wear-resistant steel. Thumbs are engineered to last.

- Range of Motion: A wider range of motion, especially with progressive link thumbs, offers greater versatility.

- Hydraulic System: The hydraulic cylinders should be robust and reliable, providing consistent clamping force. Ensure your machine has auxiliary hydraulics.

- Tine Design: Select the appropriate number and style to fit various tasks.

8. How to Choose the Right Hydraulic Thumb for Your Excavator?

Choosing the right hydraulic thumb depends on several factors:

- Your Excavator Size: Hydraulic thumbs are sized to match different excavator classes.

- Typical Applications: Consider the types of jobs you'll be performing most often.

- Budget: Pin-mounted thumbs are generally more affordable, while progressive link thumbs offer greater functionality.

- Mounting Type: Stick-mounted and pin-mounted are two primary styles.

- Main usage of thumb: Whether or not you need a thumb to create precise holes.

If you're unsure, it's best to consult with an attachment specialist. They can help you determine the perfect fit for your machine's specific needs.

9. Is Installation and Maintenance of a Hydraulic Thumb Difficult?

Installation can vary depending on the thumb type. Pin-mounted thumbs are often easier to install, as they easily fit onto the existing bucket pin. Weld-on or stick-mounted thumbs may require some welding and more complex installation procedures. Always follow the manufacturer's instructions or consult a professional.

Maintenance primarily involves:

- Regularly greasing the pivot points.

- Inspecting the hydraulic hoses and fittings for leaks.

- Checking for wear and tear on the thumb itself.

Proper maintenance will ensure long-lasting quality and performance.

10. Where Can I Find a High-Quality Hydraulic Thumb and Access Price Information?

BONOVO is a leading manufacturer of excavator attachments, including high-quality hydraulic thumbs. We are a factory specializing in the manufacturing of excavator, skid steer, and wheel loader attachments and machinery, with multiple production lines. Our products are exported to USA, North America, Europe, and Australia.

Check out our Hydraulic Demotion Rotating Grapples

One time completion of this brief form gives you immediate access to all website documents.

Completion of this brief form gives you immediate access price guide and access attachments catalog.

Time completion of this brief form gives you immediate ongoing access to all website documents.

Contact us today to discuss your needs and get a quote.

Key Takeaways:

- A hydraulic thumb dramatically increases the versatility of your excavator.

- It provides superior grip and control for material handling, demolition, landscape, arboriculture, and disaster relief.

- Hydraulic thumbs are more efficient and safer than manual thumbs.

- Choose a thumb that's compatible with your excavator and suitable for your typical applications.

- BONOVO attachments offer solutions for a range of materials.

- Thumbs are designed for various tasks including, but not limited to site prep.

- Consider a mechanical thumb if a hydraulic option is outside your budget.

- Thumbs come in various styles including, 180 degree rotation maintaining pressure throughout.

By investing in a hydraulic thumb, you're not just buying an attachment; you're investing in increased productivity, efficiency, and safety on your job sites.