The Ultimate Guide to Choosing the Right Bucket for Your Tractor & Loader - Bonovo

Are you a construction professional, landscaper, or farmer looking to enhance your tractor's capabilities? This comprehensive guide will walk you through everything you need to know about buckets and attachments for your tractor and loader. Whether you're dealing with dirt, snow, or rocks, selecting the right bucket is crucial for maximizing your tractor's productivity and efficiency. We'll cover different types of buckets, how to choose the best one for your tractor, and where to find high-quality options that fit your needs. This article is worth reading because it helps you identify the best bucket for your tractor and improve your work results, saving time and money.

1. What are the Different Types of Buckets for Tractors?

The bucket is one of the most fundamental attachments for any tractor. Choosing the right type depends on your primary application. Here's a breakdown of common bucket types:

-

Standard Bucket: This is the most versatile bucket, ideal for general dirt work, grading, and handling various materials. It's the go-to choice for most tractor owners.

-

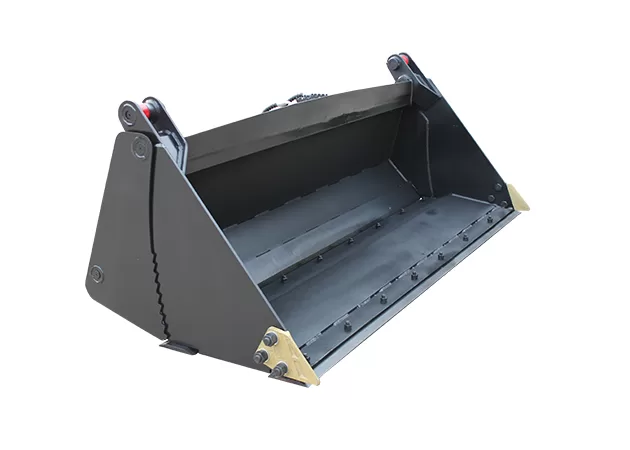

4-in-1 Bucket: This bucket is incredibly versatile. It can be used as a standard bucket, a grapple, a dozer blade, and a clam shell, making it an excellent choice for a wide array of tasks.

-

Heavy Duty Bucket: Designed for tougher tasks and materials, this bucket is reinforced for greater durability and can handle heavier loads and more abrasive materials. A heavy duty bucket is essential when working with rock or other challenging terrains.

-

Rock Bucket: Specifically designed for rock and gravel handling, these buckets often have a skeletal design with widely spaced tines or bars to allow dirt and small debris to fall through, leaving the larger rock behind.

-

Snow Bucket: This bucket is designed to efficiently move snow. They are often wider and have a higher capacity to scoop up and clear large areas of snow quickly.

-

Stump Bucket: A specialized bucket built for removing stumps. It typically has a narrow profile with a powerful tooth design, allowing for the efficient digging and prying of stumps.

-

Low Profile Bucket: This bucket is designed for ease of use. It's a low profile bucket so that the operator can see everything happening with the bucket

The tractor bucket is one of the most essential attachments for your tractor. The bucket is designed to handle many different tasks, so you can always find the perfect bucket for your work. A bucket will have a longer lifespan than many other types of attachments.

2. What Size Bucket Do I Need for My Tractor?

Choosing the right bucket size is critical for optimal performance and safety. A bucket that's too large can overload your tractor, reducing its lift capacity and potentially causing damage. One that's too small will make your tasks less efficient.

Here's how to determine the correct bucket size:

-

Tractor Weight and Horsepower: Generally, larger, more powerful tractors can handle larger buckets. Consult your tractor's specifications to determine the recommended bucket capacity.

-

Material Density: The density of the material you'll be handling is a key factor. Lighter materials like mulch or snow allow for larger buckets, while denser materials like rock or wet dirt require smaller capacities.

-

Lift Capacity: Understand your tractor's lift capacity. This is the maximum weight the loader can safely lift. Make sure the loaded bucket weight doesn't exceed this limit.

-

Application: The application also matters. If you're primarily grading, a wider bucket might be preferable for covering more ground. For digging or handling specific materials, a narrower bucket might be more suitable.

You'll want the bucket size that fits best with your tractor. Consider what size bucket is the right fit for your tractor to increase the productivity and safety of your machine.

3. What Materials Are Used to Make a Durable Bucket?

The material your bucket is made of directly impacts its durability and lifespan. Here's what to look for:

-

High-Strength Steel: This is the most common material, offering a good balance of strength, weight, and cost. Look for high-quality steel that's resistant to abrasion and impact.

-

Wear-Resistant Steel: For heavy duty applications, especially when working with rock or abrasive materials, wear-resistant steel is essential. It’s designed to withstand the constant abrasion and impact.

-

Reinforced Construction: Check for reinforcements in high-stress areas, such as the cutting edge, side plates, and corners. This adds extra strength and prevents premature wear or bending.

-

Welding Quality: The quality of the welds is crucial. Look for clean, strong welds that penetrate deeply into the steel. Poor welds can lead to cracks and failures.

-

Cutting Edge: The cutting edge should be made of hardened steel to resist wear. Some buckets have replaceable cutting edges, which can be cost-effective in the long run.

When you choose your bucket, it is vital that you choose a bucket made of high-quality materials, such as high-strength steel. Your bucket will last you for years if you choose a bucket made of good materials.

4. How Can a Stump Bucket Help You?

Removing tree stumps can be a challenging task, but a stump bucket simplifies the process significantly. Here's how:

-

Specialized Design: Stump buckets are specifically designed for digging around and prying up stumps. Their narrow profile and powerful teeth allow for efficient penetration into the soil.

-

Efficient Digging: The design of the bucket allows you to dig around the stump, cutting the roots and loosening the soil.

-

Prying Power: Stump buckets often have a curved or angled design that provides leverage for prying the stump out of the ground.

-

Versatile: While designed for stumps, these buckets can also be used for general digging, trenching, and other tasks where focused force is needed.

-

Saves Time and Labor: Compared to manual methods or other attachments, a stump bucket significantly reduces the time and effort required to remove stumps.

If you're dealing with stumps on a regular basis, a stump bucket is an invaluable attachment to add to your arsenal. The stump bucket for skid is another viable option.

5. What are the Benefits of a 4-in-1 Bucket?

The 4-in-1 bucket is one of the most versatile attachments available, offering multiple functions in a single tool. Here’s a breakdown of its benefits:

-

Multi-Functionality: As the name implies, a 4-in-1 bucket can function as a standard bucket, a grapple, a dozer blade, and a clam shell.

-

Grapple Function: The clam shell design allows you to grab and handling logs, debris, and other irregular objects that are difficult to manage with a standard bucket.

-

Dozer Blade Function: The bucket can be opened and used as a dozer blade for grading, backfilling, and spreading materials.

-

Increased Efficiency: The ability to perform multiple tasks with a single attachment saves time and increases productivity. You don't need to switch buckets as often.

-

Versatile Applications: Suitable for a wide range of applications, from construction and landscaping to agriculture and demolition.

-

Ease of Use: The hydraulic controls make it easy to switch between different functions.

A 4-in-1 bucket is a smart investment if you require versatility and efficiency on your jobs. The best 4-in-1 bucket will fit any type of machine.

6. Quick Attach vs. Pin-On Buckets: Which is Right for You?

When it comes to attaching a bucket to your tractor, you have two primary options: quick attach and pin-on. Here's a comparison to help you decide:

-

Quick Attach:

- Benefits: Allows for rapid attachment and detachment of buckets and other attachments. This saves significant time when switching between different attachments.

- Ease of Use: Very convenient and easy to operate. Most quick attach systems use a lever or latch to secure the bucket.

- Compatibility: Requires a quick attach system on your tractor. Ensure compatibility before purchasing.

- Cost: Generally more expensive than pin-on systems.

-

Pin-On:

- Benefits: Simpler and more economical. The bucket is attached directly to the loader arms using pins.

- Durability: Typically very durable. The simple design minimizes potential points of failure.

- Cost: Less expensive than quick attach systems.

- Attachment Time: Takes longer to attach and detach buckets as you need to manually insert and remove the pins.

-

Key Considerations:

- Frequency of Attachment Changes: If you frequently switch between different attachments, a quick attach system will save you significant time and effort.

- Budget: Pin-on systems are more budget-friendly.

- Existing Equipment: Consider whether your tractor is already equipped with a quick attach system. If not, you'll need to factor in the cost of installing one.

Both pin-on and quick attach systems offer benefits and drawbacks. Choosing the right one depends on your specific needs and priorities. Many times, a quick attach system is added so that you can add many different types of attachments, and the time savings pays for the cost.

7. How to Choose a Rock Bucket for Your Loader?

A rock bucket, also known as a skeleton bucket, is an essential tool for separating rock and gravel from dirt and debris. Here’s how to choose the right one:

-

Tine Spacing: The spacing between the tines or bars determines the size of the material that will pass through. For larger rock, wider spacing is preferred. For finer materials, choose a rock bucket with narrower spacing.

-

Bucket Width: Select a bucket width that matches your loader's capacity and the size of the areas you'll be working in.

-

Material and Construction: The bucket should be constructed from heavy duty materials like high-strength steel. Reinforcements are crucial for withstanding the impact of rock and abrasive materials.

-

Cutting Edge: The cutting edge should be made of hardened steel and be replaceable to extend the bucket’s lifespan.

-

Application: Consider the specific application. Are you working with a lot of large rock, or primarily handling smaller gravel? This will influence your choice of tine spacing and bucket design.

-

Compatibility: Make sure the rock bucket is compatible with your loader’s quick attach system or pin-on setup.

-

Consider the dealer: If you have a good dealer, they will be able to help you with finding the right type of rock bucket.

A rock bucket is designed to help you sift through the rock and separate it from other materials. The rock bucket can handle all the tough tasks so you don't have to.

8. What are the Advantages of a Skid Steer Bucket?

A skid steer bucket is designed for use with a skid steer loader which is a highly versatile machine used in various industries. The advantages include:

-

Versatility: Skid steer buckets are designed to handle a wide variety of materials, including dirt, gravel, snow, and debris. This versatility makes them suitable for many different tasks.

-

Maneuverability: The skid steer loader is known for its maneuverability, and the bucket is designed to take advantage of this. The machine can turn within its own footprint, making it ideal for tight spaces.

-

Quick Attach System: Like many attachments, skid steer buckets often feature a quick attach system, allowing for rapid switching between different tools. This increases productivity.

-

Durability: Skid steer buckets are often made of durable materials and are designed to withstand tough conditions. Look for buckets made of high-strength steel with reinforced construction.

-

Ease of Use: Skid steer buckets are easy to operate, and the controls are generally intuitive. This makes them easy for both experienced operators and novices.

-

Various Types: Skid steer buckets come in various types, including heavy duty, rock, and 4-in-1 buckets.

Choosing the right skid steer bucket can significantly improve your skid steer loader’s efficiency and versatility. They can also have a heavy duty design.

9. Where Can I Find High-Quality Tractor Buckets?

Finding a reliable supplier is key to ensuring you get a high-quality tractor bucket that meets your needs. Here's where you can look:

-

Equipment Dealers: Your local tractor dealer is a good starting point. They often carry a selection of buckets and can provide expert advice on the right one for your machine. They also also offer quick attach and other attachments.

-

Online Retailers: Many online retailers specialize in tractor attachments. This gives you a wide selection to choose from and lets you compare prices and features.

-

Specialized Attachment Manufacturers: Some companies focus specifically on manufacturing attachments for construction and agricultural equipment. These manufacturers often offer a broader range of options and can provide more specialized solutions. BONOVO is a good option here, as we have a large array of attachments. View our excavator attachments.

-

Trade Shows: Attending industry trade shows is an excellent way to see different buckets and attachments in person and speak directly with manufacturers.

-

Check Reviews: Before purchasing, read reviews from other customers to get insights into the quality, durability, and performance of the bucket.

When sourcing a bucket, consider both the product quality and the reputation of the supplier. A good supplier will provide excellent customer service and support and offer a warranty on their products. A good dealer can help you choose the attachment for the task. You'll need to replace the bucket if it is ever bent or damaged.

10. How to Maintain Your Bucket and Attachments?

Proper maintenance will extend the life of your bucket and ensure its optimal performance. Here’s what you need to do:

- Regular Inspections: Inspect your bucket regularly for signs of wear, such as cracks, dents, or worn cutting edges.

- Lubrication: Keep all moving parts lubricated, especially pivot points and hinge points.

- Cutting Edge Maintenance: Maintain the cutting edge by sharpening or replacing it when necessary. A sharp cutting edge will improve the bucket’s efficiency and reduce wear.

- Welding Repair: Address any cracks or damage promptly by having them professionally welded. Ignoring these issues can lead to more serious failures.

- Storage: When not in use, store your bucket in a protected area to prevent weather damage.

Following these maintenance tips will help you get the most out of your bucket and attachments, ensuring they provide reliable service for years to come. You'll also need to maintain your tractor itself. Many farmer choose to sit down and snap the bucket on their machine. Some farmers also choose to equip their machine with a quick attach.

Key Takeaways:

- Choose the right bucket type for your tractor and application.

- Select a bucket size that matches your tractor's capacity and lift.

- Opt for buckets made of high-quality, durable materials like high-strength steel.

- Consider the benefits of a 4-in-1 bucket or stump bucket for versatile tasks.

- Decide between quick attach and pin-on systems based on your needs.

- Maintain your bucket with regular inspections, lubrication, and timely repairs.

- Consider a rock grapple if you are dealing with rock.

By following this guide, you’ll be well-equipped to select the perfect bucket for your tractor, enhancing your productivity and getting the most out of your equipment. Do you need a tractor front bucket? You'll want the bucket that will provide you with the best handling. Consider your application and what the best bucket will be for you.