The Definitive Guide to Pioneer Hydraulic Coupler Styles for Quick Connection - Bonovo

Pioneer hydraulic couplers are essential components in many agricultural and industrial machines, enabling the quick and easy connection of hydraulic lines. Understanding the different styles, features, and connection methods is crucial for maintaining efficiency and preventing costly downtime – something every fleet manager like Mark Thompson values. As Allen from Bonovo, a factory specializing in high-quality construction and agricultural machinery attachments, I've seen firsthand how the right hydraulic connection can make all the difference. This guide will delve into the world of Pioneer hydraulic couplers, exploring their features, types (like the popular poppet valve design), compatibility standards like ISO 5675, and best practices for selection and use. Whether you're running tractors, skid steers, or other heavy equipment, this article will provide the insights you need to make informed decisions about your hydraulic systems.

1. What Exactly is a Pioneer Hydraulic Coupler and Why Does It Matter?

A hydraulic coupler is essentially a specialized connector designed to join hydraulic hoses together, allowing hydraulic fluid to flow between different parts of a machine or between a machine and an attachment. The "Pioneer" aspect often refers to a specific, widely adopted style of hydraulic coupler, particularly prevalent in North American agricultural equipment. Think of it like a standardized plug and socket for your hydraulic system. These couplers are designed for quick connection and disconnection, often under residual pressure, which is a huge time-saver in the field.

Why does this matter so much? Efficiency and versatility. For someone managing a fleet of equipment, like Mark Thompson, minimizing downtime is critical. Being able to swiftly change hydraulic attachments – moving from a grapple to a hammer, or connecting different implements to a tractor – dramatically increases the utility of a single machine. A reliable hydraulic coupler system ensures a secure, often leak-free, connection, preventing fluid loss (which is costly and environmentally unfriendly) and maintaining the necessary operating pressure for the hydraulic tool or function. Pioneer style couplers, due to their widespread use, also often mean easier sourcing of compatible parts.

From our perspective at Bonovo, manufacturing attachments like Excavator Buckets with Thumb or sophisticated hydraulic tools, we understand that the coupler is the critical interface. A poor connection can undermine the performance of the best attachment. Therefore, understanding the function and importance of a good hydraulic coupler, like the Pioneer style, is fundamental for anyone operating hydraulic machinery. It’s the handshake between your machine's power and the tool doing the work.

2. Are Pioneer Brand Hydraulic Couplers Worth the Price?

This is a common question, especially for budget-conscious managers like Mark who source globally. Pioneer, as an original equipment manufacturer (OEM) brand, often commands a higher price compared to aftermarket or alternative brands. Is the extra cost justified? Often, the answer lies in consistency, material quality, and proven performance. Original Pioneer hydraulic couplers are typically manufactured to stringent specifications using high-quality materials like hardened steel, ensuring durability and reliable operation over many connection cycles.

However, the term "Pioneer style" is also widely used to describe hydraulic couplers that are dimensionally compatible with the original Pioneer design, particularly the poppet valve type common in agricultural applications (often conforming to ISO 5675 series standards). Many reputable manufacturers, including factories like ours in China, produce high-quality Pioneer style hydraulic couplers that offer excellent performance and durability at a more competitive price point. The key is vetting the supplier. Look for manufacturers with robust quality control, clear specifications, and positive customer feedback.

Ultimately, the "worth" depends on the application's demands and your tolerance for risk. For critical applications where failure is not an option, sticking with the known OEM brand might provide peace of mind. But for many standard agricultural and construction tasks, a well-made Pioneer style hydraulic coupler from a trusted supplier can offer significant savings without compromising performance. It's about finding that sweet spot between price and proven reliability – a calculation Mark Thompson undoubtedly makes regularly when evaluating suppliers for products like hydraulic fittings or even larger attachments.

3. What Key Features Define a Quality Pioneer Hydraulic Coupler Product?

When evaluating a Pioneer or Pioneer style hydraulic coupler, several key features indicate a high-quality product. First and foremost is the material. Look for couplers constructed from high-strength, corrosion-resistant materials, typically hardened steel for the body and critical components. This ensures longevity, especially in demanding outdoor environments where tractors and construction equipment operate. The plating (often zinc or zinc-nickel) is also important for resisting rust and wear.

The sealing mechanism is another critical feature. Whether it's a poppet valve or ball valve design, the seals (often Nitrile/Buna-N or Viton for higher temperatures) must create a leak-free connection when coupled and minimize spillage during disconnect. Look for features like double O-rings or profiled seals that enhance sealing integrity. The valve design itself matters – a well-engineered poppet valve or ball valve ensures proper flow with minimal pressure drop when connected and provides a positive seal when disconnected.

Other important features include:

- Ease of Connection: Quality hydraulic couplers should allow for relatively easy push-to-connect operation, sometimes even under residual pressure (though connecting under zero pressure is always recommended for longevity). Locking mechanisms, like locking sleeves or ball locks, should engage securely and reliably.

- Pressure Rating: Ensure the coupler's maximum working pressure rating meets or exceeds your hydraulic system's requirements.

- Flow Rate (GPM): The coupler must handle the required hydraulic fluid flow (measured in Gallons Per Minute or GPM) without excessive heat generation or pressure drop.

- Standard Compliance: Adherence to standards like ISO 5675 ensures interchangeability with other compatible couplers. This is crucial for Mark Thompson's need for compatibility across his fleet.

- Durability Features: Look for hardened locking balls, durable springs, and designs that protect the sealing surfaces when disconnected (e.g., included dust caps or plugs).

A quality hydraulic coupler product combines robust materials, precise engineering, reliable sealing, and user-friendly operation to ensure efficient and durable performance.

4. Poppet vs. Ball Valve: Which Pioneer Style is Right for My Application?

Within the Pioneer style family, the two most common valve mechanisms you'll encounter are the poppet valve and the ball valve. Understanding the difference is key to selecting the right hydraulic coupler for your specific needs. The choice often impacts performance characteristics like flow rate, pressure drop, and spillage upon disconnection.

The poppet valve style is arguably the most traditional and widely recognized Pioneer design, especially in agricultural settings often conforming to ISO 5675. It uses a spring-loaded poppet that seals against a seat. When the male and female halves connect, the poppets push each other open, allowing hydraulic fluid flow.

- Pros: Generally lower price, widely available, good sealing in many applications, relatively simple design. Often allows connection under some residual pressure.

- Cons: Can have a higher pressure drop compared to ball valves, potentially more spillage during disconnect as the poppet valve closes, the poppet itself can be a point of wear.

The ball valve (or ball-check) style uses a spherical ball held against a seat by a spring and hydraulic pressure. When connected, the male tip pushes the ball off its seat.

- Pros: Typically offers lower pressure drop and higher flow rates for its size, often provides a more positive, leak-free seal upon disconnect (less spillage), generally considered more robust for high-cycle applications.

- Cons: Can sometimes be slightly higher in price, may be less tolerant of contamination than some poppet valve designs. Connection under pressure might be more difficult than with some poppet types.

For general agricultural tractor implement connections where the ISO 5675 standard is common, the poppet valve style Pioneer hydraulic coupler is often the default and perfectly adequate. For higher flow hydraulic systems, frequent connection cycles, or applications where minimizing spillage is critical (like sensitive environments or indoor use), the ball valve style might be the best choice. Consider your specific machine, attachment, flow (GPM) needs, and operating conditions when deciding.

5. How Do Pioneer Couplers Connect So Quickly and Reliably?

The "quick" in quick coupler is a major selling point for Pioneer style hydraulic connectors. This speed and reliability stem from their clever mechanical design. Most Pioneer style couplers operate on a push-to-connect principle. The female coupler body typically contains a retractable locking sleeve and an internal valve (poppet or ball). The male tip (or plug) has a corresponding profile and its own internal valve.

When you push the male tip into the female body, several things happen almost simultaneously:

- The male tip pushes past the locking mechanism (often steel balls held by the sleeve).

- As the male tip seats fully, it mechanically pushes open both its own valve and the valve inside the female coupler. This creates a path for hydraulic fluid flow.

- Simultaneously, the locking sleeve springs forward (or is manually engaged), forcing the locking balls into a groove on the male tip, securely locking the two halves together.

This sequence allows for a rapid, secure, and sealed hydraulic connection with a single motion. Disconnection usually involves retracting the locking sleeve, which releases the balls and allows the male tip to be pulled out. As the halves separate, the internal springs force the poppet or ball valves back onto their seats, sealing both the male and female ends and minimizing fluid loss. This reliable mechanism is why hydraulic quick couplers are indispensable on equipment ranging from farm tractors to complex construction machinery using various attachments.

6. Understanding ISO 5675: Are Pioneer Couplers Compatible?

ISO 5675 is a crucial international standard, particularly relevant in the agricultural industry. It defines the dimensions and specifications for agricultural tractor hydraulic quick couplers. The primary goal of this standard is to ensure interchangeability between couplers made by different manufacturers. If a hydraulic coupler claims conformance to ISO 5675, its male tip should connect with any ISO 5675 compliant female body of the same size, and vice versa, regardless of the brand.

Many Pioneer style hydraulic couplers, especially the traditional poppet valve types commonly found on North American farm equipment, are designed to meet or be interchangeable with the ISO 5675 series standard. This is a significant advantage for users like Mark Thompson because it simplifies sourcing replacement parts and ensures that implements or attachments can be used across different pieces of equipment that adhere to the standard. You don't necessarily need a Pioneer brand coupler to connect to an existing Pioneer ISO 5675 fitting; any coupler meeting the ISO 5675 specification should be compatible.

However, it's crucial to verify conformance. Always check the product specifications. Reputable manufacturers will clearly state if their coupler meets ISO 5675. Be aware that not all Pioneer style couplers necessarily meet this specific ISO standard, especially some specialized or older designs, or certain ball valve types which might adhere to different ISO standards (like ISO 7241-A or B). Always confirm the standard when compatibility is essential. This attention to detail prevents the costly downtime Mark aims to avoid.

7. What are the Common Uses for Pioneer Hydraulic Couplers, Especially on Tractors?

Pioneer style hydraulic couplers are ubiquitous in agricultural settings, largely due to their early adoption by major tractor manufacturers like John Deere and their alignment with the ISO 5675 series standard. On a typical farm tractor, you'll find multiple sets of these couplers (often color-coded or numbered) at the rear, sometimes at the front or mid-mount positions. Their primary use is to provide hydraulic power to a vast array of implements.

Common agricultural uses include:

- Connecting hydraulic cylinders: For lifting, tilting, and adjusting implements like plows, cultivators, planters, and balers.

- Powering hydraulic motors: Driving components on seed drills, spreaders, mowers, or hydraulic augers.

- Operating loaders and backhoes: Providing the necessary hydraulic connections for front-end loaders or backhoe attachments mounted on the tractor.

- Running specialized attachments: Powering tools like log splitters, post drivers, or hydraulic post hole diggers (Skid Steer Auger style tools can sometimes be adapted).

Beyond tractors, Pioneer style couplers are also found on other equipment where hydraulic quick connections are needed:

- Skid Steer Loaders: For connecting various attachments like grapples, breakers (Skid Steer Hammer), or augers. While skid steers often use flat-face couplers, Pioneer style might be present on older machines or certain attachments.

- Construction Equipment: Sometimes used on smaller excavators or backhoes for auxiliary hydraulic lines.

- Industrial Equipment: Utilized in various stationary or mobile hydraulic systems requiring quick changeovers.

The versatility and standardization (especially ISO 5675) make the Pioneer style hydraulic coupler a workhorse connector across many industries that rely on mobile hydraulic power.

8. How Do I Identify Male and Female Pioneer Coupler Parts?

Distinguishing between the male and female parts of a Pioneer hydraulic coupler is usually straightforward. Understanding this is essential for ordering the correct replacement part or ensuring you have the right ends to make a connection.

-

Male Coupler (Tip or Plug): The male part is characterized by its protruding tip or probe. This is the part that inserts into the female body. It will typically have an internal valve (poppet or ball) visible at the end of the probe and a groove around its circumference where the locking mechanism of the female coupler engages. Think of it as the "plug."

-

Female Coupler (Body or Socket): The female part is the receptacle. It has an opening designed to accept the male tip. You'll typically see a retractable outer sleeve (the locking sleeve) and, looking inside the opening, the face of the internal valve (poppet or ball). Inside the opening, behind the valve, are the locking balls (usually hidden by the sleeve until retracted). Think of it as the "socket."

When ordering or specifying a hydraulic coupler, you'll need to identify whether you need the male or female half, the thread size and type for connecting the hose (e.g., NPT, ORB), the body size (often related to the flow rate or ISO standard, like 1/2" body), and the valve style (poppet or ball). Knowing the difference between male and female is the first step in getting the right part for your hydraulic system.

9. Where Can I Shop for the Best Pioneer Hydraulic Coupler Products?

Finding the best Pioneer hydraulic coupler products involves considering price, quality, availability, and supplier reliability – factors Mark Thompson balances carefully. There are several avenues to shop for these essential hydraulic components:

- OEM Dealers: Dealerships for major equipment brands (like John Deere, Case IH, etc.) will stock genuine Pioneer brand hydraulic couplers or their brand-specific equivalents. This offers guaranteed compatibility and quality but often comes at the highest price.

- Agricultural Supply Stores: Stores specializing in farm equipment and parts (local co-ops, national chains like Tractor Supply) usually carry a range of Pioneer style hydraulic couplers, often including both the OEM brand and reputable aftermarket alternatives. They offer convenience and often knowledgeable staff.

- Hydraulic Specialty Shops: Businesses focused solely on hydraulic components offer expertise and a wide selection. They can help ensure you get the correct coupler type, size, and pressure/ flow rating for your specific application. They may stock various brands and styles.

- Online Retailers: Numerous online platforms, from large industrial suppliers (like Grainger, McMaster-Carr) to specialized hydraulic e-commerce sites and even platforms like Amazon or eBay, offer a vast selection of Pioneer and Pioneer style hydraulic couplers. This provides convenience and often competitive pricing, but requires careful vetting of the seller and product specifications.

- Direct from Manufacturers/Distributors: For bulk purchases or establishing ongoing supply relationships (relevant for company owners like Mark), contacting manufacturers or their authorized distributors directly can be beneficial. This is where factories like Bonovo come in – while we specialize in larger attachments, we understand the entire hydraulic system and can guide clients or source high-quality compatible components, including hydraulic couplers, often at competitive factory prices. This route requires more research but can yield significant savings and ensures direct communication regarding specifications, a key concern for Mark.

The "best" place depends on your immediate need, required quantity, price sensitivity, and desire for specific brands or technical support.

10. Maintaining Your Pioneer Hydraulic Couplers for Longevity

Proper maintenance is key to ensuring your Pioneer hydraulic couplers provide long, reliable service life and prevent frustrating leaks or connection failures. Like any hydraulic component, they aren't immune to wear and tear, but simple steps can significantly extend their lifespan. This directly addresses Mark's pain point regarding downtime caused by equipment failure.

Here are essential maintenance practices:

- Keep Them Clean: Dirt and debris are enemies of hydraulic systems. Always use dust caps on the female coupler and plugs on the male tip when disconnected. Before connecting, wipe both halves clean to prevent ingression of contaminants into the hydraulic system. Contamination can damage seals and valves.

- Inspect Seals Regularly: Check for nicks, cuts, or excessive wear on the O-rings and seals inside the coupler. Damaged seals are the primary cause of leakage. Replace them using appropriate seal kits if necessary.

- Check for Physical Damage: Inspect the coupler body, locking sleeve, and male tip for cracks, dents, or severe corrosion. Damaged components can compromise the connection's integrity and safety. Replace damaged couplers.

- Lubricate Moving Parts: Occasionally applying a light hydraulic oil to the locking sleeve mechanism and balls can help ensure smooth operation, especially in harsh environments.

- Connect/Disconnect Properly: Avoid forcing connections. If it's difficult to connect, check for residual pressure (relieve if possible), misalignment, or debris. Don't use hammers or excessive force. When disconnecting, ensure the sleeve is fully retracted.

- Store Properly: Store disconnected hoses and couplers in a clean, dry place, ensuring protective caps and plugs are securely fitted.

Regular inspection and cleaning are the most crucial steps. By incorporating these simple practices into routine equipment checks, you can maximize the life of your Pioneer hydraulic couplers and maintain the efficiency of your hydraulic attachments and implements, minimizing costly downtime.

11. Bonovo's Role: Supplying High-Quality Hydraulic Components and Attachments

At Bonovo, where I, Allen, oversee production, we understand the entire ecosystem of heavy machinery – from the mini excavators and skid steer loaders we manufacture under our DIG-DOG brand to the vast array of attachments that make these machines so versatile. While we are primarily known for robust products like excavator buckets, hydraulic hammers, grapples, and quick couplers, we recognize that even the smallest components, like hydraulic couplers, play a vital role in overall performance and reliability.

Our expertise lies in manufacturing durable equipment designed for demanding conditions. We use high-quality, wear-resistant steel and adhere to strict quality control processes. This same commitment to quality extends to the components used within our machinery and attachments. While we might not manufacture every single style of hydraulic coupler ourselves, we work closely with trusted suppliers of hydraulic fittings, including Pioneer style poppet and ball valve couplers that meet ISO standards, to ensure our customers receive compatible and reliable solutions.

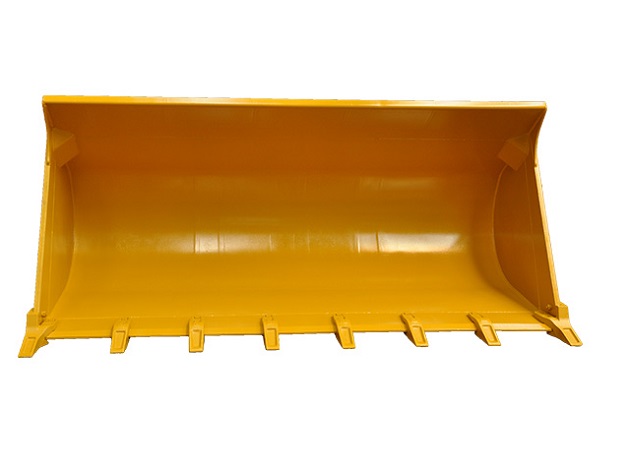

For clients like Mark Thompson, who value quality, compatibility, and competitive pricing, Bonovo offers a partnership. We can supply the heavy-duty attachments – like a powerful Rock Bucket for Wheel Loader or a versatile 4 In 1 Bucket – and ensure they integrate seamlessly with your existing hydraulic systems, including providing or advising on the appropriate hydraulic quick couplers. Our B2B model focuses on building relationships, understanding technical requirements, and delivering reliable products that enhance productivity, directly addressing the key concerns and goals of equipment owners and fleet managers worldwide.

Key Takeaways on Pioneer Hydraulic Couplers:

- Function: Pioneer style hydraulic couplers allow quick connection/disconnection of hydraulic lines, crucial for agricultural and industrial equipment versatility.

- Types: The main styles are poppet valve (common in ag, often ISO 5675 compatible) and ball valve (often better flow, less spillage).

- Quality Features: Look for robust materials (steel), reliable seals, secure locking mechanisms, proper pressure/ flow ratings, and adherence to standards like ISO 5675 for compatibility.

- Identification: The male part is the protruding tip/plug; the female part is the socket/ body with a retractable sleeve.

- Importance: They save time when changing attachments, increase machine utilization, and require proper selection and maintenance for leak-free, efficient operation.

- Sourcing: Available from OEM dealers, ag supply stores, hydraulic shops, online retailers, and directly from manufacturers/distributors – balance price, quality, and support.

- Maintenance: Keep clean (use caps/plugs), inspect seals and body for damage, lubricate sparingly, and connect/disconnect carefully.

- Compatibility: ISO 5675 is the key standard for interchangeability in many agricultural applications using Pioneer style poppet couplers. Always verify product specs.

Understanding Pioneer hydraulic couplers is essential for maximizing the productivity and reliability of your valuable hydraulic machinery and attachments.