How to Measure Your Machine to Find the Right Excavator Thumb Attachment Size - Bonovo

This article provides a comprehensive guide on choosing the correct thumb attachment for your excavator. Understanding the proper sizing and types of thumbs available is crucial for maximizing your machine's efficiency and safety. Whether you're in construction, demolition, or landscaping, this guide, brought to you by Allen from BONOVO, a leading China-based manufacturer, will make the process straightforward and effective. We serve customers like Mark Thompson in the USA, ensuring they get the best quality at competitive prices. Read on to avoid common pitfalls and ensure your excavator operates at its best!

What is an Excavator Thumb and Why Do You Need One?

An excavator thumb is a crucial attachment that significantly enhances the versatility of your excavator. Essentially, it acts like a human thumb, working in conjunction with the bucket to grasp and secure materials that a bucket alone cannot handle efficiently. Imagine trying to pick up logs, rocks, or demolition debris with just a shovel – that's the challenge without a thumb.

The addition of a thumb attachment transforms your excavator into a much more capable machine. It allows for precise picking and placing of objects, improving efficiency in tasks such as land clearing, demolition, and material handling. This is especially useful for construction companies, landscaping businesses, and demolition contractors—precisely the types of clients BONOVO serves. A thumb allows the operator to securely grip and load odd-shaped materials without an issue, preventing slippage and ensuring safe transport.

What Are the Different Types of Excavator Thumbs?

Excavator thumbs generally fall into two main categories: mechanical thumbs (also known as manual thumbs) and hydraulic thumbs. Each type has its own set of advantages and is suitable for different applications.

Mechanical thumbs are the simpler option. They are typically welded to the stick of the excavator and are adjusted manually. A mechanical thumb has a fixed range. This means that once it's set, it stays in that position until manually adjusted again. These are generally more affordable and require less maintenance since they don't have hydraulic components. However, they offer less flexibility than their hydraulic counterparts.

Hydraulic thumbs, on the other hand, offer much greater control and versatility. They are connected to the excavator's auxiliary hydraulics, allowing the operator to adjust the thumb's position from inside the cab. This provides on-the-fly adjustments, making it easier to handle a variety of materials with different shapes and sizes. While hydraulic thumbs represent a higher initial investment, the increased productivity and ease of operation often justify the cost, especially for demanding tasks.

There is a variation, it is a main pin hydraulic thumb, that is attach directly to the bucket and thumb's shared main pin pivot point.

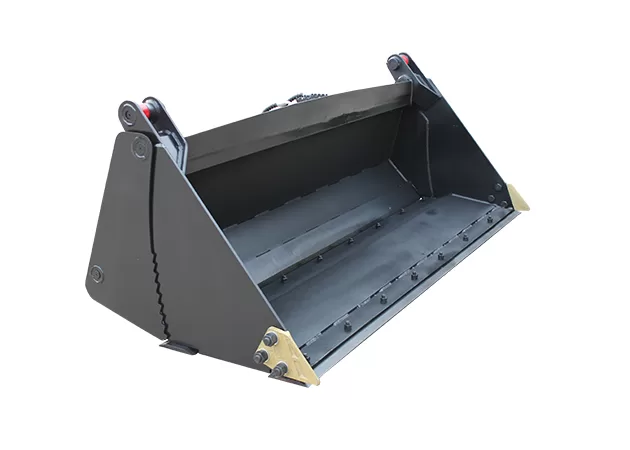

For example, BONOVO offers the Excavator Buclet with Thumb, providing a robust and reliable solution for various applications.

How Do I Determine the Correct Thumb Size for My Excavator?

Determining the correct thumb size for your excavator is paramount to ensuring proper function and avoiding damage to your machine. An improperly sized thumb can lead to inefficient operation, increased wear and tear, and even potential safety hazards.

The key factor in determining the right size is ensuring that the thumb and bucket work together seamlessly. Ideally, when the bucket is fully curled, the thumb should be able to reach and securely grip the bucket's teeth. This allows for a full and secure grasp of materials. BONOVO, as a factory specializing in excavator attachments, emphasizes the importance of precise measurements to ensure compatibility. A thumb that is too short will not be able to grip materials effectively, while a thumb that is too long can interfere with the bucket's operation and potentially damage the machine.

What is a Mechanical Thumb and How to choose?

A mechanical thumb is a type of excavator thumb attachment that is manually adjusted. Unlike hydraulic thumbs, which use the excavator's hydraulic system for movement, mechanical thumbs are typically fixed in a set position or have a limited number of adjustable positions. They are often welded onto the excavator's stick.

Choosing the Right Mechanical Thumb:

- Consider Your Needs: Mechanical thumbs are best suited for applications where frequent adjustments aren't necessary. If you primarily handle the same type of material, a mechanical thumb can be a cost-effective solution.

- Durability: Look for a mechanical thumb made from high-quality, wear-resistant steel. BONOVO, for example, uses durable materials in their manufacturing process.

- Compatibility: Ensure the mechanical thumb is compatible with your excavator's make and model. Check the manufacturer's specifications.

- Mounting Style: Mechanical thumbs can be either weld-on or pin-on. Weld-on thumbs are more permanent, while pin-on thumbs offer more flexibility for removal or replacement. The Backhoe mechanical thumb from BONOVO offers a robust and reliable solution for securing materials.

- Adjustability: Some mechanical thumbs offer limited adjustability, allowing you to change the angle of the thumb to a few preset positions.

What is a Hydraulic Thumb and it's benefits?

A hydraulic thumb is an excavator thumb attachment that utilizes the excavator's hydraulic system for movement and control. This provides the operator with the ability to adjust the thumb's position and clamping force from within the cab, offering significantly more flexibility and precision compared to a mechanical thumb.

Benefits of a Hydraulic Thumb:

- Increased Versatility: Hydraulic thumbs can handle a wider range of materials and tasks due to their adjustable nature. They can easily adapt to different shapes and sizes of objects.

- Improved Productivity: The ability to make on-the-fly adjustments saves time and increases efficiency. The operator doesn't need to leave the cab to reposition the thumb.

- Enhanced Precision: Hydraulic thumbs allow for more precise picking and placing of materials, reducing the risk of damage or spillage.

- Greater Control: The operator has full control over the thumb's clamping force, allowing for delicate handling of sensitive materials or a strong grip on heavy objects.

- Reduced Operator Fatigue: The ease of operation reduces strain on the operator, as they don't need to manually adjust the thumb.

Step-by-Step Measuring Instructions for an Excavator Thumb.

Precise measurements are vital. Follow these instructions carefully:

- Bucket Position: Fully curl your excavator bucket inward as if you were gripping an object.

- Stick Measurement: Measure the distance from the pivot point of your bucket (where the bucket connects to the stick) to the point on the stick where the thumb will be mounted. This is typically where the thumb's base plate will be welded or bolted on.

- Thumb Length: The length of the thumb should be such that when the bucket is fully curled, the thumb reaches at least to the bucket's tooth or slightly beyond. This ensures a secure grip. It is very important that the thumb must have enough length to grab the bucket efficiently.

- Width Consideration: While length is the primary concern, also consider the width of the thumb. It should be appropriately sized for the materials you typically handle. A wider thumb provides more surface area for gripping larger objects.

-

Refer to Specifications: Always double-check the manufacturer's specifications for both your excavator and the thumb attachment. These specifications will provide critical information regarding compatibility and recommended sizes.

Measurement Description Stick Measurement Pivot point of bucket to the thumb mounting point. Thumb Length Should reach at least to the bucket's teeth when fully curled. Width Consideration Wider thumbs provide better grip for larger objects. Specifications Always refer to the manufacturer's specifications for compatibility and recommended sizes.

How Does the Bucket Size Influence Thumb Selection?

The bucket size is a crucial factor in determining the appropriate excavator thumb size. The thumb and bucket work as a unit, and their dimensions must be compatible for optimal performance.

- Proportional Sizing: The thumb's length should be proportional to the bucket's size. A larger bucket generally requires a longer thumb to ensure a secure grip across the bucket's width.

- Reach and Grip: When the bucket is fully curled, the thumb should reach at least to the bucket's teeth, or slightly beyond. This ensures that the thumb can effectively clamp down on materials held within the bucket. A thumb that is too short will not be able to secure the load properly.

- Manufacturer Recommendations: Excavator and attachment manufacturers, like BONOVO, often provide guidelines or charts that specify compatible thumb and bucket sizes. Always consult these resources.

- Avoiding Interference: A thumb that is too long can interfere with the bucket's operation, making it difficult to dig or scoop materials effectively. It can also create excessive stress on the excavator's components. The general-duty excavator bucket from BONOVO is designed to work seamlessly with appropriately sized thumbs.

Can I Use a Universal Thumb Attachment for My Excavator?

The concept of a "universal" thumb attachment can be tempting, promising a one-size-fits-all solution. However, the reality is more nuanced. While some thumbs are marketed as "universal," it's crucial to understand their limitations.

- Adjustability: So-called "universal" thumbs often feature some degree of adjustability, such as multiple mounting holes or a sliding mechanism. This allows them to fit a range of excavator sizes and bucket configurations.

- Compromises: While adjustability offers flexibility, it can also lead to compromises. A "universal" thumb may not provide the same level of optimized performance as a thumb specifically designed for your excavator model.

- Compatibility Checks: Even with "universal" thumbs, it's essential to carefully check compatibility with your excavator's specifications. Pay close attention to the mounting points, operating weight limits, and hydraulic requirements (for hydraulic thumbs).

- Brand-Specific Options: Manufacturers like BONOVO often offer thumbs designed for specific excavator brands and models. These brand-specific options are generally the best choice for ensuring optimal fit and performance.

- Weld-On vs. Bolt-On: "Universal" thumbs are more commonly found in bolt-on configurations. Weld-on thumbs are typically custom-fitted to the excavator's stick and are less likely to be marketed as "universal."

How BONOVO Can Be Your Trusted Partner?

BONOVO, based in China, is a factory specializing in the manufacturing of excavator, skid steer, and wheel loader attachments and machinery. With multiple production lines, they cater to a global market, including the USA, North America, Europe, and Australia. Their business model is B2B, focusing on serving construction companies, demolition contractors, landscaping companies, and other businesses that rely on heavy equipment.

- Expertise: BONOVO's team, including experienced professionals like Allen, possesses in-depth knowledge of excavator attachments and their applications.

- Quality Materials: They use high-quality materials, such as wear-resistant steel, to ensure the durability and longevity of their products.

- Customization: BONOVO offers customization options to meet specific customer needs, ensuring that the attachment perfectly fits their machine and application.

- Competitive Pricing: As a direct manufacturer, BONOVO can offer competitive pricing without compromising on quality.

- Customer Focus: They prioritize customer satisfaction, understanding the pain points of clients like Mark Thompson, who value quality, compatibility, and reliable after-sales service.

- Global Reach: BONOVO actively participates in exhibitions, a key channel for connecting with potential customers and showcasing their product range.

- Wide Range of Products: Besides various thumbs, Bonovo offers high-quality mechanical quick coupler for a variety of machines.

What Are the Common Mistakes to Avoid When Choosing an Excavator Thumb?

Choosing the wrong excavator thumb can lead to a range of problems, from reduced efficiency to potential damage to your machine. Here are some common mistakes to avoid:

-

Incorrect Sizing: This is the most frequent error. Failing to accurately measure your excavator and bucket can result in a thumb that is either too short to grip effectively or too long, interfering with the bucket's operation. Always follow the measuring instructions carefully.

-

Ignoring Compatibility: Not all thumbs are compatible with all excavators. Factors like operating weight, hydraulic flow (for hydraulic thumbs), and mounting style must be considered. Always check the manufacturer's specifications.

-

Choosing the Wrong Type: Selecting a mechanical thumb when a hydraulic thumb would be more suitable, or vice-versa, can limit your machine's capabilities. Consider the types of tasks you perform and the level of flexibility you need.

-

Overlooking Quality: Opting for a cheaper thumb made from inferior materials can lead to premature wear, breakage, and potential safety hazards. Invest in a thumb made from durable, wear-resistant steel.

-

Neglecting Installation: Improper installation, especially for weld-on thumbs, can compromise the thumb's strength and stability. Ensure that the installation is performed by a qualified professional.

Incorrect installation of hydraulic thumbs require careful attention. -

Disregarding Maintenance: Like any piece of equipment, excavator thumbs require regular maintenance. Failing to inspect and maintain the thumb can lead to premature wear and failure.

-

Ignoring the quick coupler. If the excavator has a quick coupler, the connection dimensions need to be provided for special customization.

Summary

Here's a quick recap of the most important points to remember when choosing an excavator thumb attachment:

- Measure Accurately: Precise measurements are crucial for ensuring proper fit and function.

- Choose the Right Type: Mechanical or hydraulic, depending on your needs.

- Consider Bucket Size: The thumb and bucket must be compatible in size.

- Check Compatibility: Ensure the thumb is compatible with your excavator's make and model.

- Prioritize Quality: Invest in a thumb made from durable materials.

- Proper Installation: Ensure correct installation, especially for weld-on thumbs.

- Regular Maintenance: Inspect and maintain the thumb regularly.

- Consult the Experts: When in doubt, seek advice from a reputable manufacturer or dealer like BONOVO.

- Think about use. Thumbs are great for picking up rock, brush, debris and anything else that won't fit in a bucket.