How Many Hours is a Lot for a Mini Excavator? Understanding Mini Excavator Usage and Longevity - Bonovo

This article explores the lifespan of mini excavators, focusing on how many hours are considered "a lot" and what factors influence their longevity. We'll delve into maintenance practices, common wear points, and how to evaluate a used mini excavator, providing valuable insights for both current and prospective owners. Whether you're a seasoned contractor like Mark Thompson or new to the world of compact construction equipment, this guide will help you understand what to expect from your machine and how to maximize its lifespan.

1. What's Considered High Hours for a Mini Excavator?

The concept of "high hours" for a mini excavator is relative and depends on several factors, including the machine's maintenance history, operating conditions, and the type of work it performs. Generally, a mini excavator with over 8,000 hours might be considered high, while one with under 2,000 hours is relatively low. However, a well-maintained machine with 6,000 hours can often be in better condition than a poorly maintained one with 3,000 hours. A good machine might go over 10,000 hrs, It is a real workhorse.

The number of hours on a mini excavator is like the mileage on a car – it's an indicator of use, but not the sole determinant of condition. Think of it as a starting point for further investigation. A machine used for light landscaping work will likely have less wear than one used for heavy demolition, even if they have the same number of hours on the clock.

2. Is 5000 Hours a Lot for a Mini Excavator?

5000 hours on a mini excavator is generally considered to be in the mid-range of its lifespan. It's not necessarily "a lot," but it does indicate that the machine has seen substantial use. At this point, it's crucial to have a detailed maintenance history to assess the machine's overall condition. A mini excavator with 5000 hours that has been properly maintained and used for lighter tasks could be good for many more years of service.

However, a machine with 5000 hours that has been subjected to harsh conditions or neglected maintenance may be nearing the end of its useful life. It is like buying used cars. Pay attention to the history of the machine. Key components like the engine, hydraulic pump, and undercarriage should be carefully inspected. Some online forums suggest that, with excellent maintenance, some mini excavators can even reach 10,000 hrs, though this is less common.

3. How Does Regular Maintenance Impact Excavator Lifespan?

Regular maintenance is absolutely vital to maximizing the lifespan of any excavator, especially a mini excavator. Consistent maintenance extends the life of any machine. Think of it like taking care of your body – regular checkups and preventative care can help avoid major problems down the road. This includes routine tasks like:

- Checking and changing oil and filters.

- Greasing all pin joints and moving parts.

- Inspecting the undercarriage for wear and damage.

- Checking hydraulic hoses for leaks or cracks.

- Monitoring the engine for any unusual noises or performance issues.

- Keeping track of all service performed.

Proper maintenance not only prevents breakdowns but also helps identify potential issues before they become major, costly repairs. For example, catching a small hydraulic leak early can prevent a complete hydraulic pump failure. Addressing wear on bucket teeth promptly can prevent damage to the bucket itself.

4. What Are the Key Wear Points on a Mini Excavator?

Several key components on a mini excavator are subject to significant wear and tear. These are the areas that require the most attention during inspections and maintenance:

- Undercarriage: This includes the tracks (whether rubber or steel), rollers, idlers, and sprockets. The undercarriage bears the brunt of the machine's weight and movement, making it prone to wear, especially in abrasive conditions.

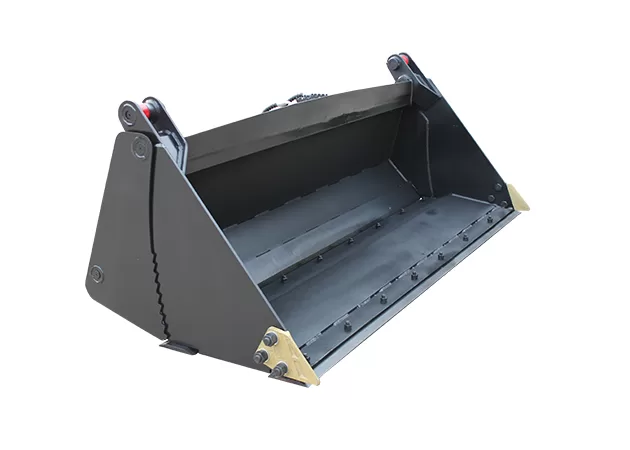

- Bucket and Attachments: The bucket, along with any attachments like hydraulic hammers, grapples, or augers, experiences direct contact with the working material. This leads to wear on the teeth, cutting edges, and the bucket structure itself.

- Pins and Bushings: These seemingly small components are critical for the smooth operation of the boom, arm, and bucket. Worn pins and bushings can lead to sloppy movement and reduced digging power.

- Hydraulic System: The hydraulic system, including the pump, valves, cylinders, and hoses, is the heart of the excavator's power. Leaks, contamination, and overheating can cause significant damage.

- Swing Motor and Bearing:The motor and bearing will eventually need to be replaced.

5. How Does Operator Skill Affect Machine Longevity?

A skilled operator can significantly extend the life of a mini excavator. Smooth, controlled movements reduce stress on the machine's components, minimizing wear and tear. Conversely, an inexperienced or aggressive operator can cause premature wear and even damage. Jerky movements, overloading the bucket, and operating the machine on unsuitable terrain can all lead to faster deterioration.

For example, an operator who consistently overloads the bucket will put excessive strain on the boom, arm, and hydraulic cylinders. An operator who frequently operates the machine on rocky or uneven ground without adjusting their technique will accelerate wear on the undercarriage. Proper training and operating practices are essential.

6. What's the Difference Between a Mini Excavator and a Standard Excavator in Terms of Lifespan?

While the basic principles of maintenance and operation apply to both mini excavators and standard excavators, there are some differences in their expected lifespans. Generally, standard excavators, being larger and heavier-duty, are built to withstand more demanding conditions and may have a longer overall lifespan. Mini excavators can and will work in many situations, and the machine is worth every penny.

However, this doesn't mean that mini excavators are inherently less durable. Their smaller size and lighter weight can actually be an advantage in certain situations, reducing stress on components. The key difference lies in the intended usage. Mini excavators are typically used for lighter tasks in more confined spaces, while standard excavators are used for heavy-duty digging and demolition. It’s vital to know your machine, and operate according to the capabilities of your machine.

7. How to Evaluate a Used Mini Excavator: What to Look For?

When buying a used mini excavator, a thorough inspection is essential. Here's a checklist of things to look for:

- Overall Condition: Check for any signs of damage, such as dents, cracks, or welds. Look for excessive rust or corrosion.

- Undercarriage: Inspect the tracks, rollers, idlers, and sprockets for wear. Check for any missing or damaged components.

- Bucket and Attachments: Examine the bucket teeth, cutting edges, and the bucket structure for wear or damage. Check any attachments for proper function.

- Pins and Bushings: Check for any play or looseness in the boom, arm, and bucket joints. Sloppy pins are a sign of wear.

- Hydraulic System: Look for any leaks in the hydraulic cylinders, hoses, and fittings. Check the hydraulic oil level and condition.

- Start the engine and listen for any unusual noises. Check for any smoke or leaks.

- Operating Hours: While the number of hours is important, consider it in conjunction with the machine's overall condition and maintenance history.

- Maintenance Records: Ask for any available maintenance records. A well-documented history is a good sign.

- Ask about previous use cases.

If possible, have a qualified mechanic inspect the machine before making a purchase. They can identify potential problems that may not be obvious to the untrained eye.

8. What Role Does the Type of Work Play in Mini Excavator Wear?

The type of work a mini excavator performs has a significant impact on its wear and tear. Machines used for heavy demolition or rock breaking will experience much faster wear than those used for light landscaping or trenching. Abrasive materials like concrete and rock are particularly hard on the bucket, teeth, and undercarriage.

Working in wet or muddy conditions can also accelerate wear, especially on the undercarriage. Mud and grit can get into moving parts, causing premature failure. Regular cleaning and maintenance are even more critical in these environments. If frequent use in harsh material is planned, consider a Rock Bucket for added durability.

9. How Do Different Brands Compare in Terms of Longevity?

Several reputable manufacturers produce high-quality mini excavators, including CAT, Bobcat, John Deere, Kubota, Takeuchi, and Yanmar. While all of these brands are known for their durability, there can be subtle differences in their design and manufacturing processes that may affect longevity.

It's best to research specific models and read reviews from other owners. Online forums and discussion groups can be a valuable source of information. Keep in mind that even the best-made machine will fail prematurely if not properly maintained. The manufacturer also plays a role. Shandong Leking Machinery Co., Ltd, for example, is known for its robust construction equipment.

10. Can You Extend the Life of a High-Hour Mini Excavator?

Yes, it is possible to extend the life of a high-hour mini excavator with careful maintenance and timely repairs. Addressing any issues promptly, such as replacing worn pins and bushings or repairing hydraulic leaks, can prevent further damage and keep the machine running longer.

In some cases, it may be cost-effective to rebuild major components, such as the engine or hydraulic pump. This can give a high-hour machine a new lease on life, but it's important to weigh the cost of the repair against the machine's overall value. Regular inspection will help you track the lifespan of different components.

Remember, even with the best care, every machine eventually reaches the end of its useful life. The key is to maximize its lifespan through proper maintenance and operation and to recognize when it's time to replace it. A good dealer can help you determine the best course of action for your specific situation. Check the seal, ram, swivel and belt for wear.

Summary: Key Takeaways for Mini Excavator Longevity

- Regular maintenance is the single most important factor in extending the life of a mini excavator.

- "High hours" is a relative term; a well-maintained machine with many hours can be better than a neglected one with fewer hours.

- Key wear points include the undercarriage, bucket and attachments, pins and bushings, and hydraulic system.

- Operator skill plays a significant role in minimizing wear and tear.

- The type of work performed greatly impacts the rate of wear.

- Thorough inspection is crucial when buying a used mini excavator.

- Consider the brand, but prioritize maintenance history.

- Even high-hour machines can have extended life with proper care and repairs.

- Always use the right attachment for the job. For instance, use a 4 In 1 Bucket for versatile tasks.

- Don't Forget, BONOVO also offers robust Excavator Bucket Pins.

- Any questions, start a new thread at a forum to find latest articles.