Excavator Bucket Maintenance: Signs to Replace Stick Nose

Maintaining excavator buckets in optimal condition is paramount for safety and efficiency in construction and excavation operations. One critical aspect of excavator bucket maintenance involves knowing when to replace stick noses, also as known pins and bushings, components essential for smooth operation. In this article, we'll explore the signs indicating it's time for replacement and the risks associated with delaying repairs.

Excavator buckets are versatile machines, handling a myriad of tasks with precision and power. However, like any equipment, they require regular maintenance to ensure peak performance and longevity. Among the maintenance tasks, monitoring the condition of pins and bushings is crucial. These components play a pivotal role in the structural integrity and functionality of the excavator bucket's arm assembly.

Signs of Stick Noses Wear and Replacement

Detecting signs of wear on excavator bucket stick noses(pins and bushings) is vital for preemptive maintenance. One common indicator is slack or movement observed at the pivot point during operation, often referred to as excavator bucket tilt. This movement, whether static or dynamic, signifies potential wear and tear in the assembly. Delaying replacement beyond this point can lead to more extensive repairs, increasing downtime and costs.

Risks of Delaying Repairs the Stick Noses

The consequences of procrastinating on pin and bushing replacement can be severe. Failure to address wear promptly may result in irreversible damage, rendering the equipment inoperable. In cases where replacement is overdue and parts have started to move during operation, field repairs become challenging and may require welding and drilling to restore integrity. Moreover, prolonged use of worn pins and bushings can lead to increased fatigue and wear on surrounding components, exacerbating the problem.

Stick Nose Maintenance: Key for Excavator Performance and Safety

The timely replacement of excavator bucket is imperative for maintaining equipment performance and safety. Ignoring signs of wear can lead to costly repairs, downtime, and compromised functionality. excavator bucket operators are advised to conduct regular visual inspections and adhere to maintenance schedules to ensure optimal operation. Remember, proactive maintenance not only enhances equipment reliability but also minimizes the risk of accidents and unforeseen expenses. >>Refer to excavator parts

Arrange Equipment Service for Your Stick Noses

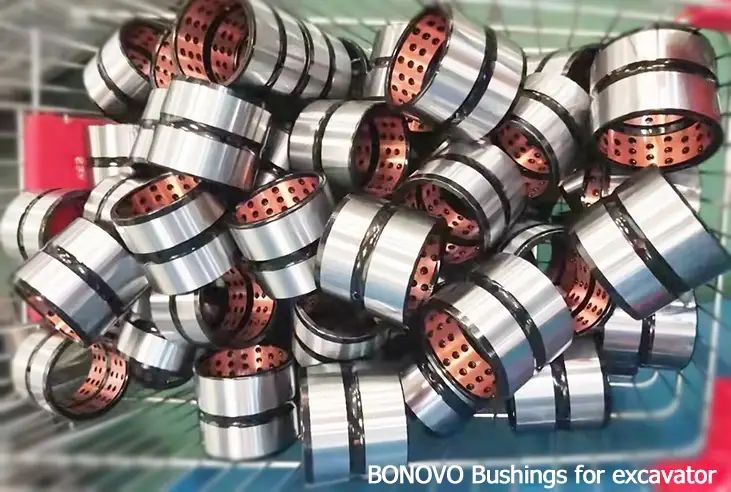

For replacement pins and bushings, contact BONOVO, a trusted manufacturer of excavator attachments based in China. With quality components and expertise, BONOVO ensures reliable solutions for your excavator bucket maintenance needs. After completing repairs, prioritize proper lubrication to prolong the lifespan of new pins and bushings, safeguarding your investment for years to come.