Backhoe vs. Wheel Loader: Understanding the Key Differences Between These Loaders - Bonovo

Choosing the right heavy equipment is crucial for maximizing efficiency and profitability on any construction site or project. Two popular choices, the backhoe loader and the wheel loader, often cause confusion. While both are powerful machines used in earthmoving and material handling, they have distinct designs, primary functions, and ideal applications. This article dives deep into the difference between a backhoe and a wheel loader, exploring their features, strengths, weaknesses, and the types of jobs they excel at. Understanding these key differences will help you, whether you're a company owner like Mark Thompson or a fleet manager, make an informed decision about which piece of equipment best suits your specific requirements and operational needs. We'll look at everything from their basic structure to the attachments they use, ensuring you have the knowledge to invest wisely.

1. What Exactly is a Backhoe Loader?

Let's start with the backhoe loader. Think of it as the multi-tool of the construction equipment world. Its most defining feature is that it has attachments at both ends. At the front, you typically find a large bucket, similar to what you see on other loaders and wheel loaders, designed for pushing, scooping, and loading materials. But the real star of the backhoe is at the rear: an articulated arm with a smaller bucket attached, specifically designed for digging. This articulated arm and small bucket assembly is the "hoe" part of the name. This dual functionality makes the backhoe loader incredibly versatile.

The operator's seat in a backhoe loader can usually swivel 180 degrees, allowing the operator to easily switch between controlling the front bucket and operating the backhoe arm at the rear without leaving the cab. This unique setup allows a single machine to perform tasks that might otherwise require two separate pieces of equipment used on a construction site, like an excavator and a loader. Backhoe loaders are the perfect solution for jobs requiring both digging and loading in relatively confined spaces.

Imagine you need to dig a trench for utility lines and then immediately backfill it or load the excavated soil onto a truck. A backhoe loader can handle both tasks efficiently. The rear backhoe digs the trench, and then the operator swivels around to use a backhoe's front loader bucket to move dirt or load it. This versatility is a major advantage for general construction, landscaping, and utility work. Many backhoes typically come in various sizes, offering different digging depths and bucket capacities.

2. And What Defines a Wheel Loader?

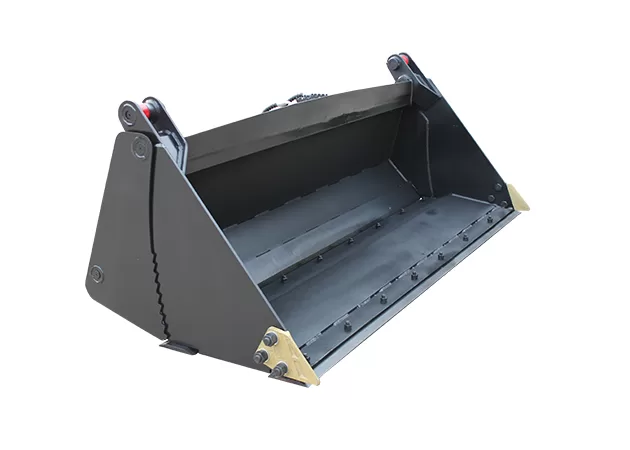

Now, let's look at the wheel loader, sometimes called a front loader or bucket loader. Unlike the backhoe loader, the wheel loader is primarily designed for one main task: material handling. It features a large bucket on the front, mounted on boom arms that allow it to lift significant amounts of material. Wheel loaders typically have an articulated frame, meaning the machine bends in the middle for steering (i.e., they articulate), which gives them excellent maneuverability in open areas despite their often larger size compared to backhoe loaders.

The core function of a wheel loader is to scoop, lift, carry, and load loose material like gravel, sand, soil, snow, debris, and rubble. You'll commonly see them on a construction site, in quarries, mining operations, and large landscaping projects, efficiently moving large volumes from one place to another or loading trucks. Their design prioritizes lifting capacity and cycle speed for loading tasks. While they don't have the built-in digging arm of a backhoe, their robust front linkage and powerful hydraulic systems make them exceptionally good at what they do.

Wheel loaders are available in a huge range of sizes, from compact models suitable for smaller job sites to massive machines used in heavy-duty mining. The focus is purely on the front bucket operation, making them specialized and highly efficient for loading and transporting materials. While the primary attachment is the bucket, this bucket can be replaced with other tools like forks or specialized buckets, adding some versatility, though not to the extent of a backhoe loader. Their powerful engines and sturdy construction are built for heavy-duty tasks involving moving substantial volumes.

3. What are the Primary Functional Differences Between Backhoe Loaders and Wheel Loaders?

The most significant functional difference between backhoe loaders and wheel loaders lies in their core design philosophy. The backhoe loader is a versatile, multi-purpose machine designed to both dig and load. It combines the functions of an excavator (with its rear backhoe arm) and a loader (with its front bucket). This makes it ideal for tasks that require both capabilities in succession or in areas where deploying two separate machines isn't practical or cost-effective. It's the jack-of-all-trades on many construction projects.

Conversely, the wheel loader is a specialist. It's optimized almost entirely for material handling – scooping, lifting, carrying, and loading large volumes quickly and efficiently. Its design, featuring a large front bucket, powerful lift arms, and often articulated steering, is geared towards maximizing loading capacity and speed. While you can do some light scraping or site cleanup with a wheel loader, it's not designed for digging trenches or precision excavation like the backhoe arm of a backhoe loader. The wheel loader excels where bulk material handling and leveling are the primary requirements.

Think about the typical workflow. If your job involves digging a foundation (excavate), then moving the spoil (move dirt), and perhaps lifting some materials into place, the backhoe loader shines. If your primary task is loading thousands of cubic yards of gravel from a stockpile onto trucks all day long, the wheel loader's superior capacity and cycle time make it the far more efficient choice. The difference between backhoe functionality and wheel loader specialization is central to choosing the right earthmoving equipment.

4. Backhoe vs. Wheel Loader: Comparing Size and Maneuverability

Size and maneuverability are other key areas where these two machines differ significantly. Backhoe loaders are generally more compact than most wheel loaders, especially when comparing machines with similar bucket capacities at the front. Their design, often based on a tractor chassis, usually results in a smaller turning radius, particularly for rigid-frame models. This makes the backhoe loader well-suited for working in tighter spaces, like residential construction sites, urban utility work, or landscaping projects where navigating around obstacles is common.

Wheel loaders, particularly the larger models, are built for volume and power, which translates to a larger physical footprint and higher operating weight. While their articulated steering (articulate) allows for surprisingly tight turns relative to their size, they generally require more open space to operate efficiently than a backhoe loader. They excel in larger, more open areas like quarries, large construction sites, stockyards, and agricultural settings where vast amounts of material need to be moved without the constraints of tight quarters.

The choice often comes down to the environment. Need a machine that can navigate a crowded job site, dig a trench near a building, and then load a small dump truck? The backhoe loader's agility is a major plus. Need to load high-sided trucks rapidly from a large stockpile in an open yard? The wheel loader's size, stability, and loading capacity are advantageous. Consider the typical worksite conditions you encounter most often when weighing this factor. Maneuverability in confined spaces often favors the backhoe, while open-area productivity favors the wheel loader.

5. How Does Attachment Versatility Differ Between a Backhoe and a Wheel Loader?

Versatility through attachments is a hallmark of modern construction equipment, and both backhoe loaders and wheel loaders offer options, but in different ways. The backhoe loader is inherently versatile due to its two distinct working ends. The rear backhoe arm isn't just limited to a digging bucket; it can be fitted with various attachments like a hydraulic hammer (breaker) for demolition, an auger for drilling holes, a grapple for handling logs or debris, or a compactor plate. The front loader end can also swap its standard bucket for forks, brooms, snowplows, or a 4 In 1 Bucket For Skid Steer Loader (many attachments are cross-compatible with appropriate couplers). This dual-end attachment capability makes the backhoe loader exceptionally adaptable.

Wheel loaders, while primarily focused on their front bucket operations, also offer considerable attachment versatility at the front end. The standard bucket can be replaced with numerous tools depending on the application and wheel loader size. Common attachments include pallet forks, log grapples, specialized buckets (like high-tip or Rock Bucket for Wheel Loader), snow blowers, brooms, and even tree spades. While they lack the secondary working end of the backhoe, the range of front-mounted tools allows wheel loaders to perform various tasks beyond simple loading materials, particularly in industries like agriculture, forestry, and waste management.

So, which is more versatile? It depends on your definition. The backhoe loader offers a broader range of task types (digging, loading, breaking, drilling) thanks to its two functional ends. The wheel loader offers deep specialization in material handling but can adapt to various types of materials and front-end tasks with different attachments. If you need a single machine to dig and load and potentially run other hydraulic tools from either end, the backhoe loader often wins. If your focus is high-volume front-end work with adaptability for different materials, the wheel loader with the right attachment set might be better. We, as a factory, produce a wide array of attachments for both backhoe and wheel loader platforms, understanding the need for this flexibility.

6. Can You Explain the Key Differences in Digging Capabilities?

This is where the fundamental design difference between backhoe loaders and wheel loaders is most apparent. The backhoe loader is explicitly designed for digging tasks, thanks to its rear-mounted backhoe arm and bucket. This articulated arm provides significant reach below ground level and the ability to excavate with precision. It's ideal for digging trenches for utilities, excavating foundations for small buildings, digging irrigation ditches, and other tasks requiring controlled digging. The operator has a clear view of the digger end and precise control over the arm and bucket, making it suitable for delicate work around existing structures. A backhoe is essentially part excavator.

Wheel loaders, on the other hand, are not primarily digging machines in the same way. Their front bucket is designed for scooping and loading loose material that is already excavated or piled up. While a skilled operator can use the wheel loader's bucket to scrape away topsoil, level ground, or dig into relatively soft, loose banks, it lacks the reach, digging depth, and precision of a backhoe arm. Attempting deep excavation or trench digging with a wheel loader is inefficient and can put undue stress on the machine. Its strength lies in surface work and handling material, not subterranean excavation.

Therefore, if your primary need involves significant digging below grade, trenching, or precision excavation, the backhoe loader is the clear choice. Its dedicated backhoe assembly is purpose-built for these construction tasks. If your work involves only surface-level grading, site cleanup, or moving already excavated material, the wheel loader might suffice, but for anything deeper or more precise, the backhoe is superior. Even a mini excavator offers more dedicated digging capability than a wheel loader, highlighting the wheel loader's focus on loading.

7. Which Machine is Better for Material Handling: Backhoe Loader or Wheel Loader?

When the primary task is material handling – specifically, loading trucks, hoppers, or moving large volumes of material around a worksite – the wheel loader generally holds a significant advantage over the backhoe loader. Wheel loaders are purpose-built for this. They typically boast larger bucket capacities, higher lift capacities, greater dump height, and faster cycle times compared to the front loader portion of a similarly sized or priced backhoe loader. Their powerful engines and robust hydraulic systems are optimized for continuous loading operations.

The articulated steering of most wheel loaders also contributes to their efficiency in loading cycles, allowing for quick maneuvering between the pile and the truck or hopper. The operator sits facing forward with an excellent view of the bucket and the loading target. This specialization translates directly into higher productivity for bulk material handling and leveling tasks. Large models can move massive amounts of material very quickly, making them indispensable in quarries, batch plants, and large-scale earthmoving projects.

While the backhoe loader can perform loading tasks with its front bucket, it's generally not as efficient as a dedicated wheel loader for high-volume work. Its front loader capacity and reach might be less, and its cycle times slower. The operator might also need to swivel the seat depending on the task flow, which can add time. However, for smaller scale loading materials, backfilling trenches it just dug, or jobs where versatility is more important than sheer loading speed, the backhoe loader's front bucket is perfectly adequate. Think of it as capable loading vs. specialized, high-efficiency loading. If loading is your main game, the wheel loader is usually the better bet.

8. Are There Specific Construction Projects Where One is Clearly Preferred?

Yes, absolutely. The unique strengths of each machine make them better suited for certain types of construction projects.

Backhoe loaders truly shine in:

- Utility Work: Digging trenches for pipes, cables, and conduits, then backfilling. Their size allows access to urban and suburban areas.

- Small-Scale Excavation: Foundation digging for houses or small buildings, pool excavation.

- Landscaping: Creating berms, digging for tree planting (landscape), minor grading, and moving materials like mulch or soil on residential or commercial properties. A Tree Spade Attachment for Skid Steer / Excavator / Wheel Loader can sometimes be adapted, but the backhoe's digging precision is often key.

- General Construction / Municipal Work: Roadside repairs, culvert placement, small demolition tasks (often with a hammer attachment), and general site cleanup where both digging and loading are needed intermittently.

- Farming: Various tasks like ditch clearing, loading feed, and light excavation.

Wheel loaders are the preferred choice for:

- High-Volume Material Handling: Loading trucks in quarries, sand and gravel pits, asphalt plants, and large earthmoving projects.

- Large-Scale Loading/Transport: Moving large quantities of loose material across a large construction site or industrial yard.

- Heavy Civil Construction: Road building (loading base materials), dam construction, large site preparation.

- Mining and Aggregate Operations: Primary movers of processed materials.

- Waste Management: Moving and loading waste at transfer stations or landfills.

- Snow Removal: Particularly for large parking lots, roads, and commercial properties, often equipped with large snow buckets or pushers.

The choice often depends on the primary activity. If digging is frequent, the backhoe loader is often essential. If loading volume is paramount, the wheel loader excels. Understanding the main range of tasks on your typical job site will help you make an informed decision.

9. Considering Cost and Maintenance: Backhoe Loaders vs. Wheel Loaders

Cost is always a major factor for business owners like Mark. Generally speaking, backhoe loaders tend to have a lower initial purchase price compared to wheel loaders of similar engine power or front loader bucket size. This is partly due to their often simpler, tractor-based design compared to the heavy-duty, purpose-built frames and components of many wheel loaders. However, prices vary widely based on size, features, and brand (e.g., Mahindra EarthMaster vs. other brands). Used machines also offer significant cost savings for both types.

Maintenance costs can be more complex to compare. A backhoe loader has two distinct working systems (front loader and rear backhoe), including more hydraulic cylinders, pins, and bushings, which could potentially mean more points of wear and maintenance on the excavator side. However, components might be less heavy-duty than those on a comparably sized wheel loader designed for constant, heavy loading cycles. Wheel loaders, while having fewer primary functions, are built robustly for high-stress loading, and their components (engine, transmission, hydraulics, articulation joint) are often designed for extreme durability, which can sometimes translate to higher replacement part costs, though potentially longer intervals between major repairs if well-maintained.

Routine maintenance (fluids, filters, greasing) is critical for both machines. Access for daily checks and servicing is usually well-thought-out on modern equipment used in the construction industry. When considering long-term costs, think about:

- Initial purchase price (new or used).

- Expected maintenance frequency and cost of parts (e.g., Bushings for Excavator & Loader).

- Fuel consumption (often higher on larger wheel loaders due to more powerful engines).

- Potential downtime cost vs. versatility (can the backhoe do the work of two machines, saving rental costs?).

10. How Do I Make the Right Choice for My Business Needs?

Making the make the right choice between a backhoe loader and a wheel loader boils down to carefully analyzing your primary business activities and specific requirements. Ask yourself these questions:

- What percentage of my work involves digging vs. loading? If digging (trenches, foundations) is a significant and frequent part of your work, the backhoe loader's integrated backhoe is invaluable. If your work is overwhelmingly focused on loading and transporting materials in bulk, the wheel loader's efficiency is hard to beat.

- What are my typical worksite conditions? Do you frequently work in tight, confined spaces (favoring the backhoe loader's maneuverability) or large open areas (where a wheel loader can operate most effectively)? Do you need to travel between sites on roads (often easier and legal for backhoe loaders)?

- What volume of material do I need to move? For high-volume, continuous material handling, the larger bucket capacities and faster cycle times of a wheel loader offer significant productivity gains. For smaller volumes or intermittent loading, the backhoe loader is sufficient.

- How important is versatility? Do you need one machine to perform a wide range of tasks, including digging, loading, lifting, breaking (hammer), or drilling (auger)? The backhoe loader is the king of versatility, potentially eliminating the need for multiple machines like a mini excavator plus a skid steer or small wheel loader.

- What is my budget? Consider the initial purchase price, ongoing maintenance, fuel costs, and potential return on investment based on the machine's productivity in your specific applications. Don't forget the cost and availability of necessary attachments.

- What other equipment do I already own? Does the new machine need to complement existing equipment (e.g., using the same attachments) or fill a specific gap in your fleet? Perhaps you already have an excavator and just need efficient loading (favoring a wheel loader), or maybe you need a single machine for smaller jobs (favoring a backhoe loader).

By honestly assessing these factors, reviewing the key differences we've discussed, and perhaps even demoing both types of loader are two distinct options, you can make an informed decision that best supports your business's efficiency and profitability. As manufacturers, we see customers succeed with both backhoe loaders and wheel loaders – the key is matching the machine to the mission.

Key Takeaways: Backhoe Loader vs. Wheel Loader

- Backhoe Loader: A versatile machine with a front loader bucket and a rear backhoe digging arm. Excellent for tasks requiring both digging and loading, especially in confined spaces. Offers great attachment flexibility on both ends. Generally more maneuverable and has a lower initial cost.

- Wheel Loader: A specialized material handling machine with a large front bucket and articulated steering. Optimized for high-volume loading, carrying, and transporting materials quickly in open areas. Offers significant front attachment versatility focused on loading different materials. Higher loading capacity and faster cycle times.

- Primary Function: Backhoe loaders dig and load; Wheel loaders primarily load and carry.

- Digging: Backhoe loaders excel at trenching and excavation; Wheel loaders are limited to surface work and handling loose material.

- Loading: Wheel loaders are generally much more efficient for high-volume loading than backhoe loaders.

- Site Conditions: Backhoe loaders are better for tight spaces; Wheel loaders thrive in open areas.

- Choice: Base your decision on your primary tasks, site conditions, volume requirements, versatility needs, and budget.

Choosing the right piece of equipment is vital. We hope this comparison helps clarify the difference between backhoe loaders and wheel loaders, empowering you to select the best machine for your construction, landscaping, or material handling needs.