Severe Duty Rock Bucket For Excavator 10-50 Tons

BONOVO specializes in manufacturing excavator rock buckets and backhoe severe duty rock buckets. Our products are engineered to withstand highly abrasive conditions, offering superior wear protection and extended lifespan. Designed for continuous digging in the toughest environments, we provide various grades of high wear resistance steel and ground engaging tools to meet your specific needs.

In order to achieve a more perfect flt, bonovo can customlze the size according to the needs of customers.

10-50 ton

MATERIAL

HARDOX450,NM400,Q355

WORKING CONDITIONS

Mainly used for digging hard soil, mixed with a relative soft stone and clay, softer stones and other light load operating environment.

capacity

0.5-3CBM

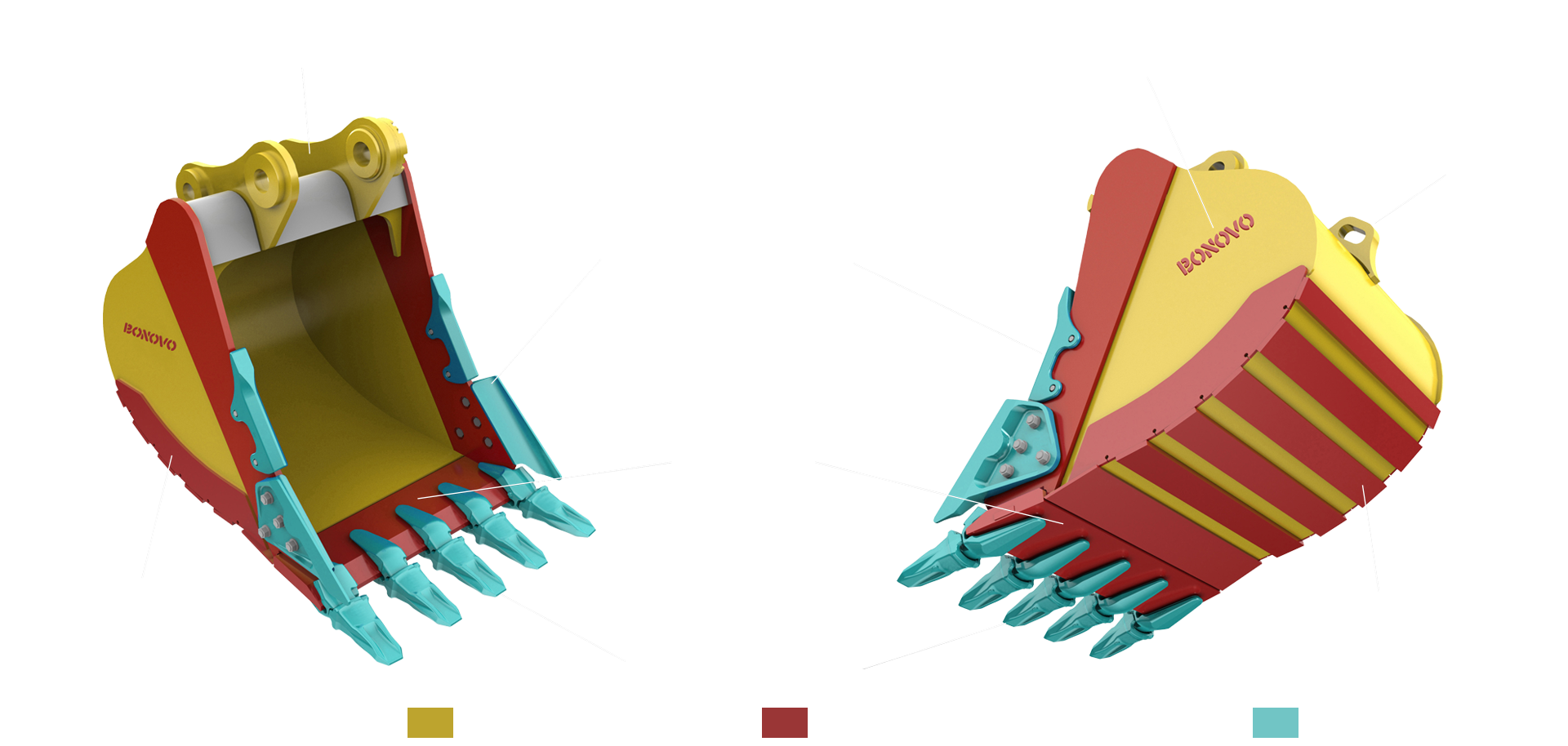

BONOVO Severe-duty Rock Bucket

Designed for excavating hard and rocky geology with increased durability and performance. The rock bucket working conditions are mostly hard soil, mixed with soft gravel, gravel and other heavy-duty operations, its application conditions are relatively bad, so it is necessary to use high-strength steel, and the thickness of the steel plate is thickened, about 20% heavier than the same tonnage standard bucket, the side teeth have become a stronger guard, and the bucket teeth use rock teeth.

BONOVO, a premier manufacturer specializing in excavator rock buckets and backhoe severe duty rock buckets, boasts extensive production expertise and formidable technical prowess. Committed to delivering top-tier, long-lasting bucket solutions, we cater to evolving customer requirements. As industry frontrunners, we prioritize precision and innovation, ensuring our buckets set the benchmark for performance and reliability. Widely deployed in construction, road maintenance, and beyond, our products earn acclaim from satisfied clientele.

Specification

| Commonly used tonnage parameters: | |||||

| Tonnes | Bucket Type | Width | G.E.T | Bucket Pins | Weight/kg |

| 12T | SEVERE-DUTY BUCKET | 30''-762mm | J250 series | including | 388 |

| 4pcs | |||||

| 15T | SEVERE-DUTY BUCKET | 36''-915mm | J300 series | including | 600 |

| 5pcs | |||||

| 18T | SEVERE-DUTY BUCKET | 42''-1067mm | J350 series | including | 815 |

| 5pcs | |||||

| 20T | SEVERE-DUTY BUCKET | 48''-1220mm | J350 series | including | 1085 |

| 5pcs | |||||

| 25T | SEVERE-DUTY BUCKET | 54''-1372mm | J400 series | including | 1407 |

| 6pcs | |||||

| 30T | SEVERE-DUTY BUCKET | 60''-1524mm | J450 series | including | 1725 |

| 6pcs | |||||

| 36T | SEVERE-DUTY BUCKET | 60''-1524mm | J450 series | including | 1725 |

| 6pcs | |||||

| 49T | SEVERE-DUTY BUCKET | 66''-1676mm | J550 series | including | 2370 |

| 6pcs | |||||

Details

Bucket Ear

The position of the bucket ear adopts multi-layer welding bead to ensure the overall strength of the structure, reduce the amount of heat input, reduce the deformation, reduce the probability of defects, and the bushing adopts the integral boring process to ensure the concentricity of the bucket ear sleeve and higher precision.

Tooth Adapter

The tooth adapter welding is first hotter about 200 degrees before welding, the side teeth on both sides are welded with the side knife, and the welding bead is extended to the connection with the main cutter and the arc plate, which ensures the overall strength of the main cutter of the bucket body, and the bucket teeth on both sides are stronger during the working process.

Painting

Difference colors can be chosen as per request to fit different machines. Before painting, sand blasting process will be also used to be prepared for the better appereance. Two times painting are used to enhances color durability.