Extreme Duty Bucket 20-400 Tons/2-11 Cbm

Bonovo Excavator Extreme Duty Buckets 20-400 Tons are designed for the most demanding mining applications, where durability and performance are paramount. These buckets are made from high-strength materials and are engineered to withstand the rigors of extreme service conditions, including abrasive materials and heavy loads. With a capacity range of 20 to 400 tons, these buckets are suitable for a wide range of excavators and mining equipment, ensuring efficient and reliable material handling. Whether you’re working in open-pit mines, quarries, or other heavy-duty construction sites, Excavator Extreme Duty Buckets 20-400 Tons are the perfect choice for maximizing productivity and extending equipment lifespan.

In order to achieve a more perfect flt, bonovo can customlze the size according to the needs of customers.

20-400 ton

MATERIAL

HARDOX450,NM400,Q355

WORKING CONDITIONS

Mainly used for digging hard soil, mixed with a relative soft stone and clay, softer stones and other light load operating environment.

Capacity

2-11CBM

BONOVO, a professional construction bucket manufacturing factory, has rich production experience and superb technical strength. We are committed to providing high-quality, durable bucket products to meet the changing needs of our customers. As an industry leader, we pay attention to detail and innovate to ensure that our buckets deliver superior performance and reliability in the marketplace. Our products are widely used in construction, road construction and maintenance and other fields, and are well received by customers.

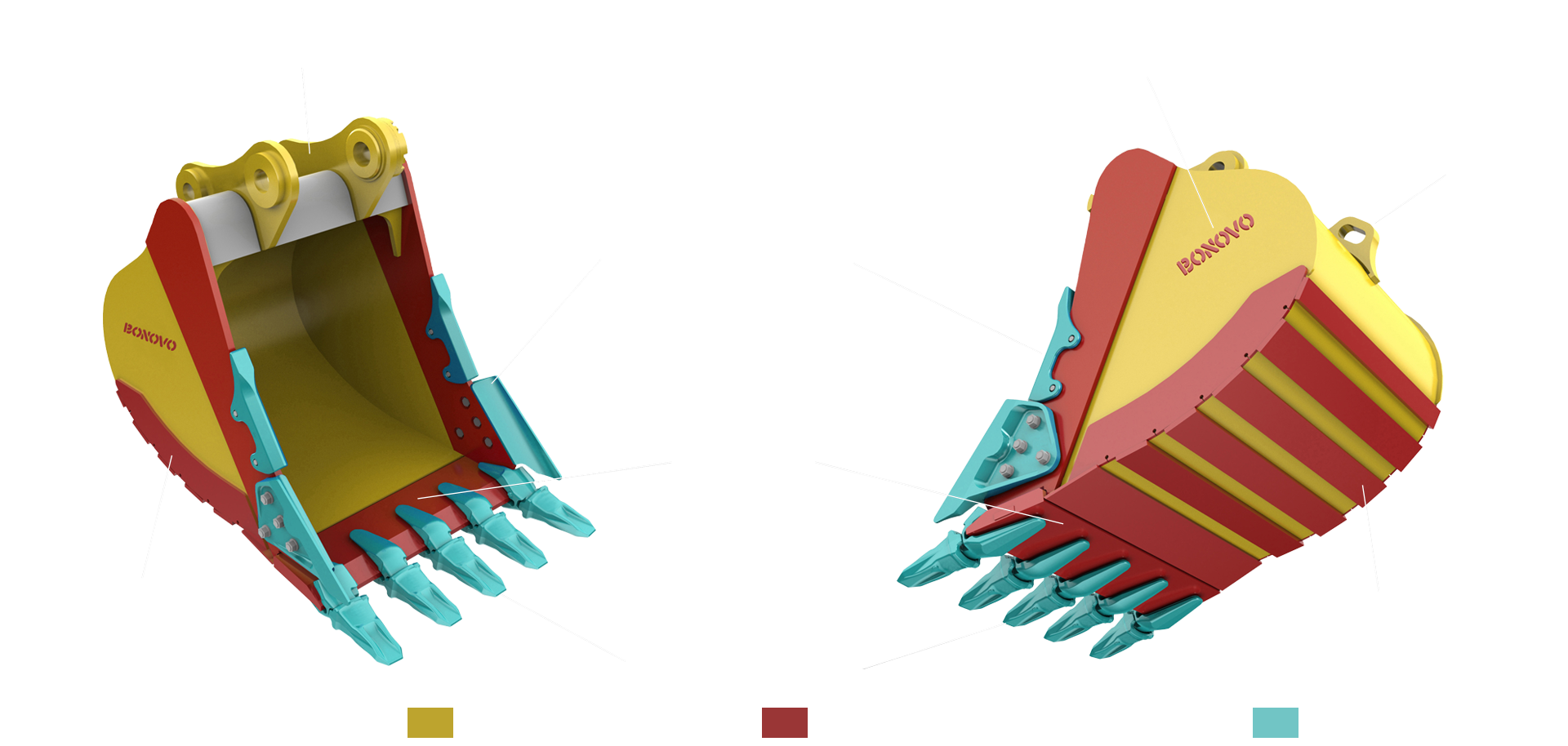

Extreme Duty Bucket

Quarry bucket is more severe than rock bucket working conditions, mostly used for hard stone, secondary solid stone, regolith fossil, solid stone, ore, etc., and requires a lot of high-intensity excavation operations when working, so it is based on the rock bucket parts need to be reinforced in key areas, the bottom increases the reinforcement plate, increases the side protection plate, installs the protective plate, and uses high-strength wear-resistant steel materials for high-stress and wear-prone parts Line manufacturing. This digging bucket has strong wear resistance and bending ability.

The feature about BONOVO Excavator Extreme Duty Buckets 20-400 Tons :

Purpose-built for mining operations: Excavator Extreme Duty Buckets are specifically designed for the most demanding mining applications, where durability and performance are essential.

High-strength materials: These buckets are made from robust materials that can withstand the rigors of extreme service conditions, including abrasive materials and heavy loads.

Wide capacity range: With a capacity ranging from 20 to 400 tons, these buckets are suitable for a variety of excavators and mining equipment, ensuring efficient and reliable material handling.

Versatile use: Ideal for use in open-pit mines, quarries, and other heavy-duty construction sites, these buckets maximize productivity and extend equipment lifespan.

Backbone of efficient mining operations: With their robust design and exceptional performance, Excavator Extreme Duty Buckets are the key to efficient and durable mining operations.

Specification

| Commonly used tonnage parameters: | ||||||

| Tonnes | Bucket Type | Width | G.E.T | L-Guard | Bucket Pins | Weight/kg |

| 20T | Extreme Duty Rock | 48''-1220mm | J350 series | HS175-140 10pcs | including | 1282 |

| 5pcs | ||||||

| 25T | Extreme Duty Rock | 54''-1372mm | J400 series | HS175-140 10pcs | including | 1681 |

| 6pcs | ||||||

| 30T | Extreme Duty Rock | 60''-1524mm | J450 series | HS175-140 10pcs | including | 2122 |

| 6pcs | ||||||

| 36T | Extreme Duty Rock | 60''-1524mm | J450 series | HS175-140 10pcs | including | 2122 |

| 6pcs | ||||||

| 49T | Extreme Duty Rock | 66''-1676mm | J550 series | HS175-140 10pcs | including | 2735 |

| 6pcs | ||||||

Details of our specifications

Bucket Ear

The position of the bucket ear adopts multi-layer welding bead to ensure the overall strength of the structure, reduce the amount of heat input, reduce the deformation, reduce the probability of defects, and the bushing adopts the integral boring process to ensure the concentricity of the bucket ear sleeve and higher precision.

Tooth Adapter

The tooth adapter welding is first hotter about 200 degrees before welding, the side teeth on both sides are welded with the side knife, and the welding bead is extended to the connection with the main cutter and the arc plate, which ensures the overall strength of the main cutter of the bucket body, and the bucket teeth on both sides are stronger during the working process.

Painting

Difference colors can be chosen as per request to fit different machines. Before painting, sand blasting process will be also used to be prepared for the better appereance. Two times painting are used to enhances color durability.