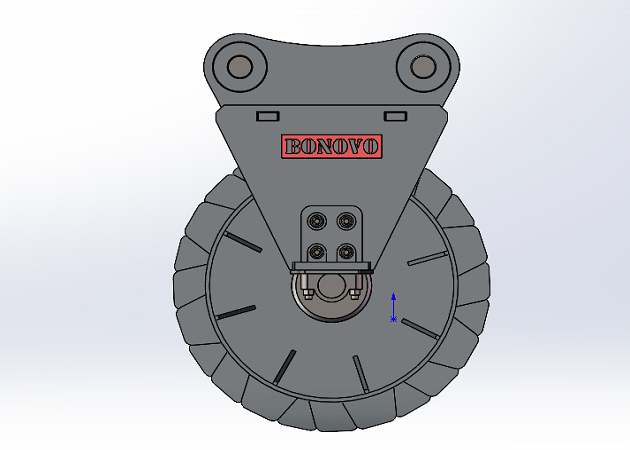

BONOVO Compactor Wheel for Excavator

The BONOVO excavator compaction wheel features three padded wheels on a single axle. Its heavy design boosts compaction efficiency, needing less power and fewer passes, leading to time, cost, fuel, and maintenance savings.

In order to achieve a more perfect flt, bonovo can customlze the size according to the needs of customers.

1-40 Ton

MATERIAL

NM400

WORKING CONDITIONS

compact various soil layers and gravel, gravel and other fill materials

Compaction Wheel

Overview of Excavator Compaction Wheels

Excavator compaction wheels are essential attachments designed to replace vibrating compactors in compaction tasks. Compared to vibrating compactors, these tools have a simpler structure, are more economical, durable, and exhibit a low failure rate. They represent the most fundamental mechanical properties required for effective compaction.

Features of BONOVO Compaction Wheels

The BONOVO excavator compaction wheel is built with three separate wheels, each with pads welded around the circumference. These wheels are secured by a common axle, with excavator hanger brackets attached to bushed brackets between the wheel sets on the axles. This heavy design enhances the compaction process, requiring less power from the excavator, reducing the number of passes needed to complete the job. This efficiency not only saves time and operator costs but also reduces fuel consumption and maintenance expenses.

Specification

| Tonnage | weight/kg | Wheel width A/mm | Wheel diameter B/mm | Maximum working diameter C/mm | Roller model D |

| 1-2T | 115 | 450 | 380 | 470 | PC100 |

| 3-4T | 260 | 450 | 380 | 470 | PC100 |

| 5-6T | 290 | 450 | 450 | 540 | PC120 |

| 7-8T | 320 | 450 | 500 | 600 | PC200 |

| 11-18T | 620 | 500 | 600 | 770 | PC200 |

| 20-29T | 950 | 600 | 890 | 1070 | PC300 |

| 30-39T | 1080 | 650 | 920 | 1090 | PC400 |

Advantages of Excavator Compaction Wheels

Efficient Compaction: The excavator compaction wheel exerts significant compaction force, quickly compacting various soils and loose materials, thereby improving operational efficiency.

Strong Adaptability: These wheels can be mounted on excavator tracks or wheels, making them suitable for diverse terrains and construction conditions.

Multiple Uses: Beyond soil compaction, the excavator compaction wheel can also compress and crush rocks, branches, and other materials.

Ease of Operation: The compactor wheel is easy to operate, with adjustable compaction speed and strength controlled via the excavator's throttle and operating lever.

Applications of Excavator Compaction Wheels

The excavator compactor wheel is ideal for compacting loose materials such as soil, sand, and gravel. Typically installed on excavator tracks or wheels, the compaction wheel comprises a wheel body, bearings, and compaction teeth. During operation, these teeth crush and compact materials to achieve density.

Maintenance and Durability

Excavator compaction wheels are crafted from high-strength materials, such as high-strength steel and wear-resistant components, ensuring durability and reliability. Proper maintenance includes keeping the wheel body clean and lubricated, and regularly inspecting components like bearings and compaction teeth to ensure optimal operation and prolonged service life.

Procurement Guidance

For high-quality, durable excavator compaction wheels, BONOVO offers a reliable solution. Visit BONOVO’s website or contact their sales team to learn more about their compaction wheels and other excavator attachments, ensuring you get the best equipment for your construction needs.

Details of BONOVO Compaction Wheel for Excavator

Roller

Use rollers instead of bearings to rotate the wheel body. Rollers are maintenance-free and have a longer service life than bearings. The size of the roller determines that the overall width of the compactor wheel will not be too large.

Wheel

The wheel body of the compaction wheel is hollow designed to reduce the weight of the product.

The wheel body is made of two circular steel plates and a rolled plate into a circular arc plate welded on the supporting wheel. Triangular ribs are welded between the circular plate and the arc plate to reinforce the wheel body.

Wheel block

The wheel block is made of steel plate, which has the advantage of being strong and wear-resistant, but the disadvantage is that it is heavy and the overall weight of the product is heavy. Hollow castings can be used instead. Wheel block sorting can be customized according to customer requirements.