China OEM Mcloughlin J1t Mini Excavator – Amphibious Excavator – Bonovo

The sprocket/segment engages with the bushing of track link assembly and drives the machine. The proper heat treatment is essential to long life and durability. BONOVO segments and sprockets are subject to multiple quality checks throughout the manufacturing process to ensure they meet the stringent specifications. Our sprockets are applicable for Komatsu, Hitachi, Kobelco, Daewoo, Hyundai, Volvo, Jcb etc. We can also offer OEM service according to your drawings or samples.

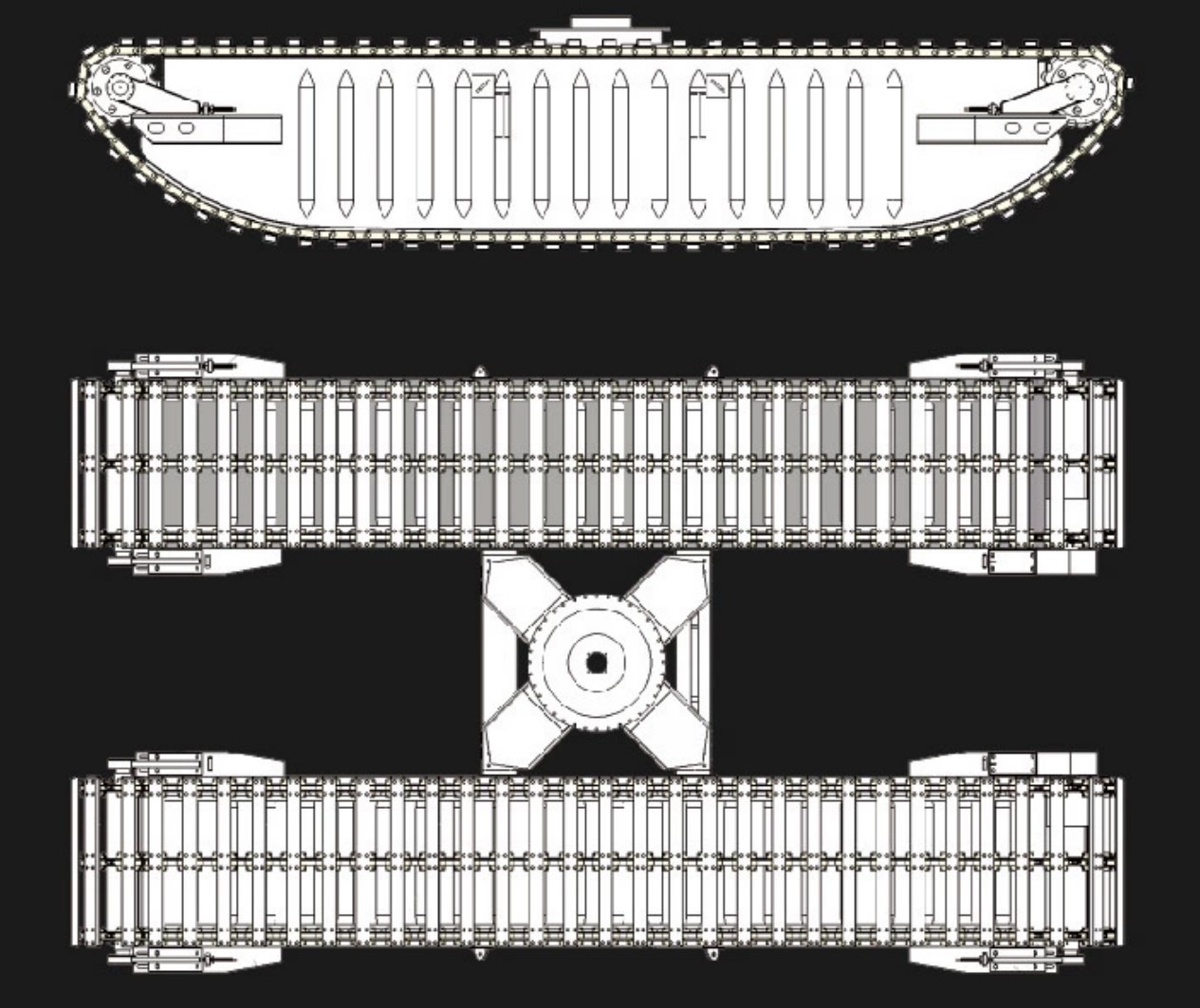

Overall 3D and structural drawings:

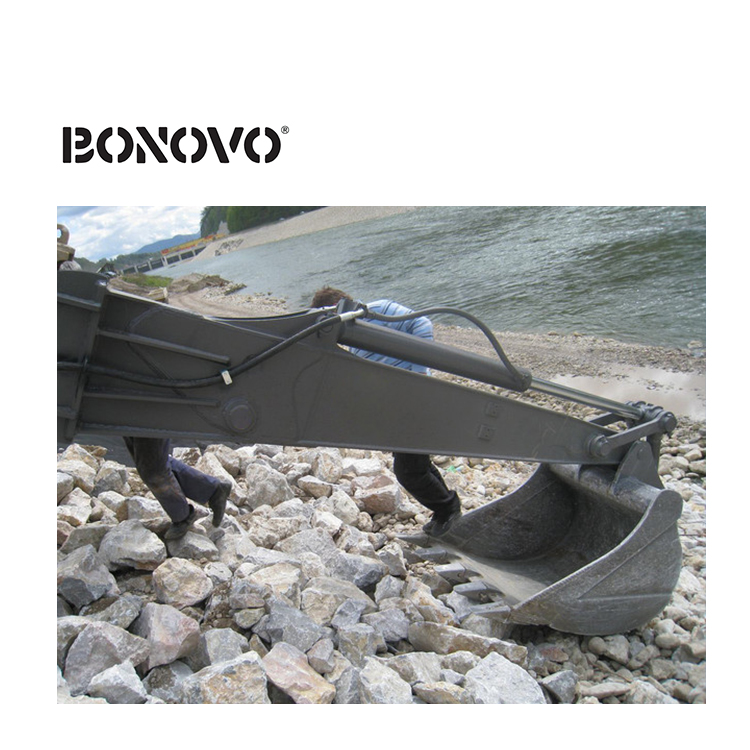

Spud Poles System

The Spud and Hydraulic Mechanism are integrated in the closed vice pontoon, which are installed on both sides of the amphibious excavator. The hydraulic power can be used to control the tilting or up-and-down positioning. Its length is determined by the depth of the working area. The spuds are erected when working, then be inserted into the mud by hydraulic mechanism. The use of spuds will greatly improve the stability of equipment operation in water.

Undercarriage structure drawings:

Amphibious Specifications

Technical advantages

Manufacturing, testing procedures & applications

Trial operation & multi-function testing - long-way walking & dredging pump

Applicable Environment:

- Swamp land clearing at mining, plantation and construction area Wetland restoration and reclamation

- Flood prevention and control Water diversion project Transformation of saline-alkali and low-yield land Deepening of canals, river channel and river mouth Clearing of Lakes, shorelines, ponds and rivers

- Digging trenches for oil& gas pipe laying and installation

- Water irrigation

- Landscape building and natural environment maintenance