Line Boring Machine 60mm

In order to achieve a more perfect fit, Bonovo can customize the size according to the needs of customers.

| Model | BM-40 | BM-50 | BWM-50S | BWM-50P | BM-60 | BM-60S |

| Main motor | 1.5KW brushless DC motor | 1.5KW brushless DC motor | 3KW vertical servo motor | 3KW servo motor | 2KW DC servo motor | 2KW DC servo motor |

| Tool feed motor power | 120W | |||||

| Main motor output speed | 125 rpm | 125 rpm | 0-300 rpm | 0-300 rpm | 100 rpm | 80 rpm |

| Motor speed regulation | Infinitely variable speed | Continuously variable speed can realize forward and reverse rotation | ||||

| Feeding method | Hand-in-hand | |||||

| Boring bar diameter | 40mm | 50mm | 50mm | 50mm | 60mm | 60mm |

| Boring range | 45-200mm | 55mm-260mm | 55mm-260mm | 55mm-260mm | 65--500mm | 65-500mm |

| Feed stroke | 380mm | 380mm | 200mm | 200mm | 420mm | 740mm |

| Maximum number of cuts on one side | 2-3mm | 2-3mm | 3mm | 2mm | 2-3mm | 2-3mm |

| Processing roundness | 0.03mm | 0.03mm | 0.02mm | 0.03mm | 0.03mm | 0.05mm |

| Roughness | 3.2um | 3.2 | 3.2 | 3.2 | 3.2um | 3.2um |

| Installation method | Welding fixation | Welding fixation | Welding fixation | Welding fixation | welding | welding |

| Welding hole range | * | * | 55-230mm | 55-230mm | * | * |

| Single side welding thickness | * | * | 3-4mm | 2-3mm | * | * |

| Welding wire model | * | * | 1.0 | 1.0 | * | * |

| Matching accessories | boring bar 1.5m long: 1 tool holder: 1 top plate: 1 clip blades: 1 box tool handle: 1 centering sleeves: 4 (2 large and 2 small) support seats: 2 a set of tools |

boring bar 1.5m long: 1 tool holder: 1 top plate: 1 machine clamp blades: 1 box tool handles: 2 top tool sleeve: 1 centering taper sleeves (two large and two small): 4 support seats: 2 support bolts: 8 a set of tools |

Machine head: 1 set, boring bar diameter 50mm, tool bar 1.5m long: 1 tool bar long 600: 1 support seat: 2 tiles support: 1 lock buckle: 1 support bolt: 8 centering sleeves: 4 tool holder: 1 top plate: 1 oil can: 1 trap: 1 hexagonal wrench: 1 clamp blades: 1 box (10 pieces), machine clamp handle: (16*16 handle one Root, one 12*12 tool handle) top tool sheath: 1 spare small screw: 1 pack of wire feed hose: 2 main welding machine connection cables: 1 1.2m long welding gun rod: 1 30cm long welding gun rod : 1 centering sleeve: 1 protective cover: 3 contact tips: 3 |

CNC display screen: 1 machine head: 1 unit, boring bar diameter 50mm tool bar 1.5m long: 1 tool bar long 600: 1 support seat: 2 support tile frame: 1 lock buckle: 1 support bolt: 8 centering sleeve: 4 tool holders: 1 top plate: 1 oil can: 1 trap: 1 hexagonal wrench: 1 set of machine clamp blades: 1 box (10 pieces), machine clamp tool handle: ( One 16*16 tool handle, one 12*12 tool handle) top tool holder: 1 spare small screw: 1 pack wire feed hose: 2 main welding machine connection cable: 1 1.2m long welding gun rod: 1 30 cm long welding gun rod: 1 centering sleeve: 1 protective cover: 3 contact tips: 3 |

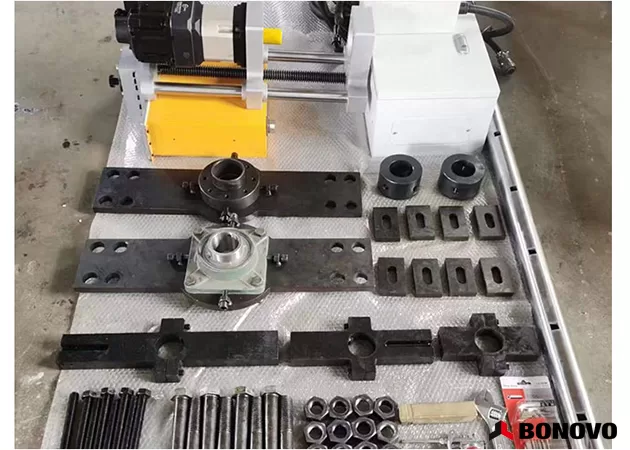

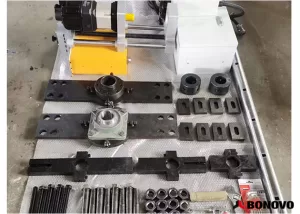

machine head: 1 tool bar 2m long: 1 support seats: 2 centering device: 1 tool holders of different specifications: 3 support bolts: 8 blades: 1 box tool handle: 1 oil pot: 1 flexible A wrench: 1 hexagonal wrenches: 1 |

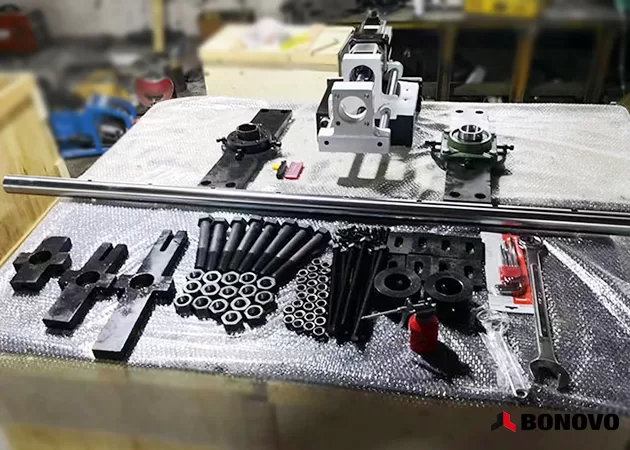

spindle box: 1 tool feed box: 1 electric motor: 1 boring bar 2m long: 1 3 types of auxiliary tool holders (choose different specifications of tool holders according to the size of the machining hole), machine clamp blades: 1 box machine A knife handle: 1 a complete set of tools, supporting seats: 1 centering devices: 1 set screw rod: 1 |