Overview

The "Digger Bucket Cutting Edge" is a crucial component of excavators and other heavy machinery used in construction, mining, and agriculture. This part plays a significant role in the efficiency and durability of the equipment. BONOVO, a Chinese leading manufacturer that offers customized solutions, rapid delivery, and OEM services.

Importance of the BONOVO Cutting Edge

1. Efficiency: The sharpness and durability of the cutting edge determine how easily the bucket can penetrate tough materials. A well-maintained cutting edge reduces the effort required by the machine, leading to increased productivity.

2. Durability: The cutting edge bears the brunt of the wear and tear during digging operations. A high-quality cutting edge prolongs the lifespan of the bucket and the machine itself, reducing downtime and maintenance costs.

3. Precision: A sharp cutting edge provides cleaner cuts, leading to more precise excavation and reduced spillage of materials.

Types of BONOVO Cutting Edges

There are several types of digger bucket cutting edges, each designed for specific applications:

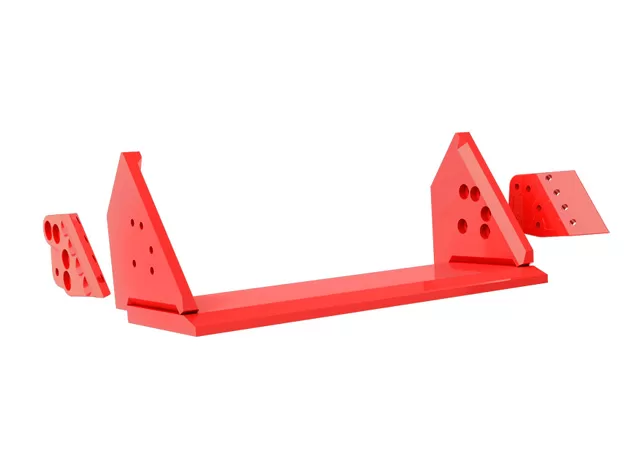

1. Straight Cutting Edge: The most common type, suitable for general digging and loading.

2. Serrated Cutting Edge: Features a toothed design, ideal for cutting through hard and abrasive materials like rock and compacted soil.

3. Reversible Cutting Edge: Can be flipped when one side wears out, effectively doubling the lifespan of the cutting edge.

4. Bolt-On Cutting Edge: Easily replaceable, as it is attached to the bucket with bolts. This type is convenient for maintenance and replacement.

Materials Used for BONOVO Cutting Edges

The materials used for making cutting edges are selected for their hardness, toughness, and resistance to wear:

1. High-Carbon Steel: Offers a good balance between strength and affordability. Commonly used for general-purpose cutting edges.

2. Heat-Treated Boron Steel: Known for its superior hardness and wear resistance, making it suitable for heavy-duty applications.

3. Chromium Carbide: Provides excellent wear resistance, often used in extremely abrasive conditions.

BONOVO: Your Partner for Customized Cutting Edges

When it comes to high-quality digger bucket cutting edges, BONOVO stands out as a premier manufacturer. BONOVO offers a wide range of cutting edges that can be tailored to meet the specific needs of your machinery and applications.

1. Customized Solutions: BONOVO provides bespoke cutting edge solutions tailored to your specific requirements, ensuring optimal performance and compatibility with your equipment.

2. Rapid Delivery: With an efficient manufacturing process and a commitment to customer satisfaction, BONOVO ensures fast delivery times, helping you minimize downtime and keep your projects on schedule.

3. OEM Services: BONOVO offers OEM services, allowing you to get cutting edges branded and produced according to your specifications. This service is ideal for businesses looking to maintain brand consistency and high-quality standards.

For top-notch cutting edges and customized solutions, consider partnering with BONOVO. Their commitment to quality, rapid delivery, and OEM services makes them an ideal choice for all your digger bucket cutting edge needs. Contact BONOVO today to learn more about how they can support your business and enhance your equipment's performance.