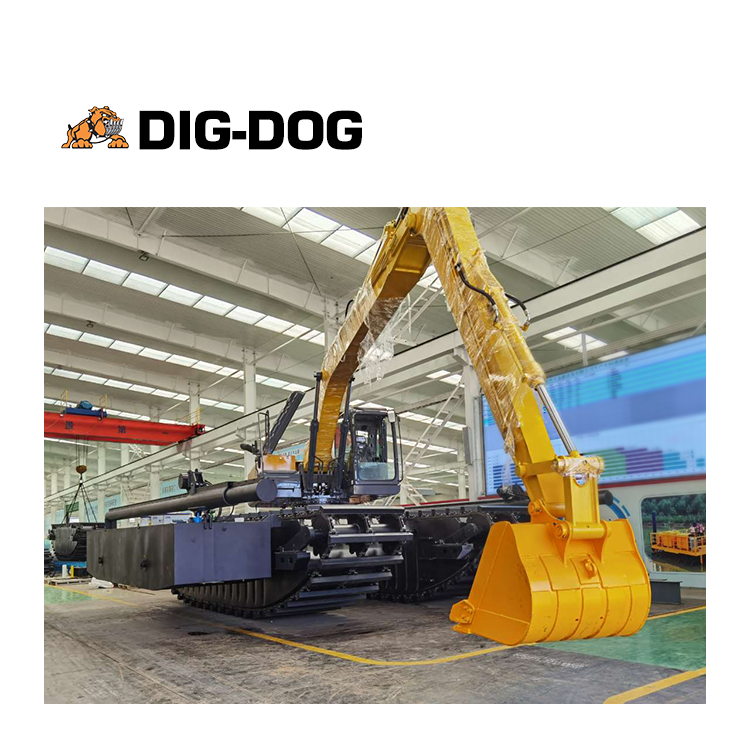

Amphibious Excavator 3-50 Ton

Bonovo offers worldwide dredging solutions, featuring our cutting-edge floating excavators. Explore our range of amphibious excavators, cutter suction pumps, and amphibious dredging equipment.

Amphibious excavator is also called floating excavator, which is specially designed to function effectively on rivers, swampy lakes, canals and settling pond rehabilitation areas. We have professional team to design and custom made high quality and versatile models of amphibious excavators for all major brands of excavators ranging from 5 to 50 tons. Bonovo team can offer different project solutions including dredging pump, long-way walking, loading platform, sectional barge and long reach arms.

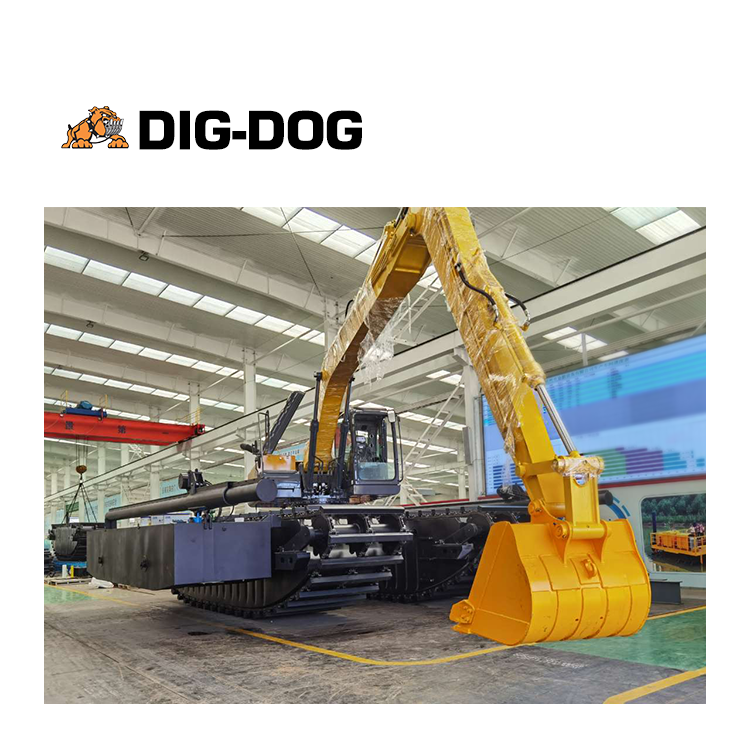

Spud Poles System

The Spud and Hydraulic Mechanism are integrated in the closed vice pontoon, which are installed on both sides of the amphibious excavator.

The hydraulic power can be used to control the tilting or up-and-down positioning. Its length is determined by the depth of the working area.

The spuds are erected when working, then be inserted into the mud by hydraulic mechanism.

The use of spuds will greatly improve the stability of equipment operation in water.

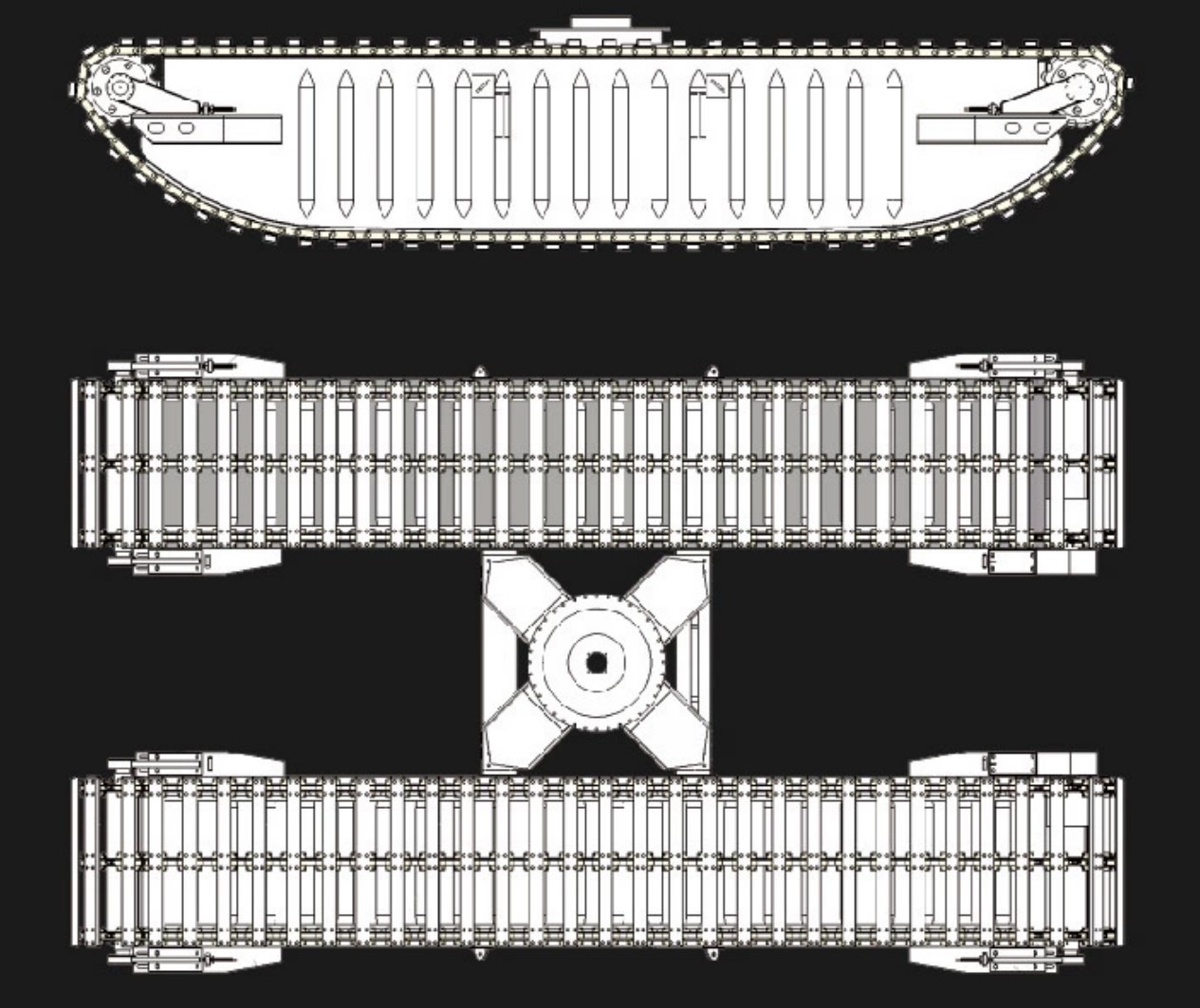

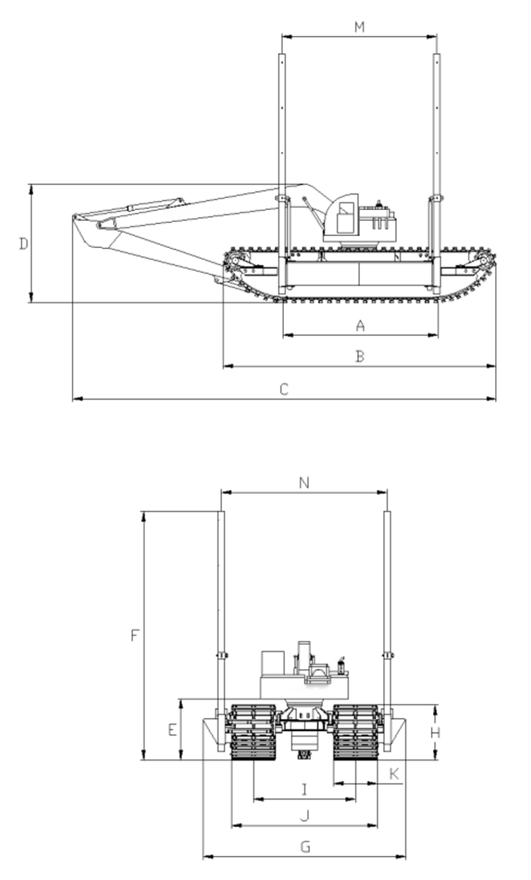

Undercarriage structure drawings

Retractable Pontoon

Retractable Pontoon means the distance can be adjusted automatically between two pontoons in a certain range.

During construction working, in case of narrow working environment, pontoons in-between distance can be minimized during working.

With the function of space adjusting, we can help enhance the chassis stability and improve work efficiency of customers.

Specification

| Description | Amphibious Undercarriage Models | ||||||||

| AP-50(3T-5T) | AP-80(6T-10T) | AP-140(11T-15T) | AP-180(16T-19T) | AP-200(20T-24T) | AP-250(25T-27T) | AP-300(27T-30T) | AP-350(35T-40T) | AP-400(40T-50T) | |

| Pontoon Grounded Length (mm) | 1200 | 2000 | 3500 | 4500 | 5000 | 6000 | 6500 | 7000 | 7000 |

| Undercarriage Length (mm) | 5200 | 5700 | 6200 | 8500 | 9500 | 10500 | 10500 | 11500 | 13500 |

| Overall Length (mm) | 6100 | 7260 | 8070 | 10290 | 11460 | 13300 | 13610 | 14480 | 14480 |

| 7300 | 9550 | 11300 | 12950 | 14450 | 14450 | 15450 | 15950 | 15950 | |

| 8500 | 10550 | 12300 | 13950 | 15750 | 15750 | 16750 | 17100 | 17100 | |

| Overall Height (mm) | 2600 | 3700 | 3770 | 2870 | 3950 | 3980 | 4040 | 4140 | 4800 |

| Counterweight Ground Clearance (mm) | 1510 | 1810 | 2010 | 2010 | 2010 | 2010 | 2010 | 2200 | 2540 |

| Spuds Height (mm) | 6000 | 6000 | 6000 | 8000 | 8000 | 10000 | 10000 | 12000 | 12000 |

| Overall Width (mm) | 4700 | 5500 | 6160 | 6360 | 6800 | 6800 | 8000 | 8000 | 8000 |

| Pontoon Height (mm) | 1340 | 1640 | 1840 | 1840 | 1840 | 1840 | 1840 | 2040 | 2340 |

| Track Gauge (mm) | 2700 | 3500 | 3660 | 3660 | 3700 | 3700 | 4700 | 4700 | 4700 |

| Overall Width (mm) | 3700 | 4500 | 5160 | 5160 | 5200 | 5200 | 6400 | 6400 | 6400 |

| Pontoon Width (mm) | 1000 | 1300 | 1500 | 1500 | 1500 | 1500 | 2000 | 2000 | 2000 |

| Spuds Cross Range (mm) | 3500 | 4000 | 4500 | 5000 | 5600 | 5600 | 5600 | 6000 | 6000 |

| Spuds Width (mm) | 4100 | 4900 | 5560 | 5560 | 5600 | 5600 | 6800 | 7000 | 7000 |

Technical Advantages

The Pontoon material is made of AH36 vessel special material and 6061T6 aluminum alloy with high strength material.

The anti-corrosion treatment adopts sandblasting and shot-blasting technology, which effectively improve the usage life.

Reasonable structural design and finite element analysis on-site destructive testing ensure the bearing capacity and safety of the Pontoon.

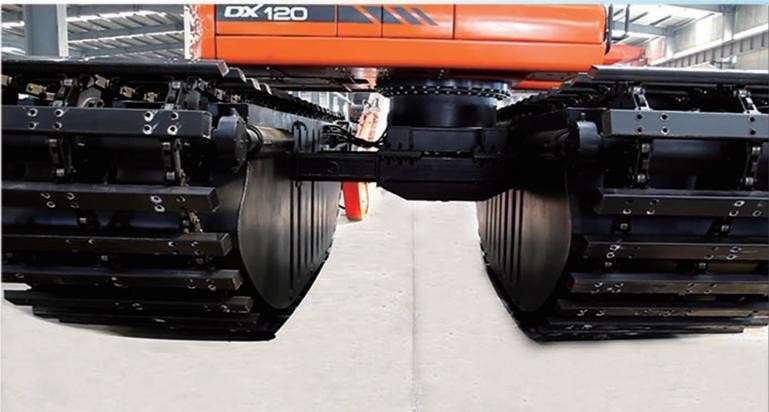

Chains Design

After the chain being used for a period of time, the pitch will increase due to wear of pin bushing, which will make the whole chain become longer and resulted into chain shedding or slippery when walking. It will seriously affect the operation. The tensioning device can ensure the chain pin and driving gear teeth properly engaged by adjusting the position of the sprocket. The bolt tightening is standard configuration of our pontoon. Cylinder tightening is much easier than bolt tightening, which can make balance adjustment and ensure more stable and efficient walking.

Applicable Environment

- Swamp land clearing at mining, plantation and construction area Wetland restoration and reclamation

- Flood prevention and control Water diversion project Transformation of saline-alkali and low-yield land Deepening of canals, river channel and river mouth Clearing of Lakes, shorelines, ponds and rivers

- Digging trenches for oil& gas pipe laying and installation

- Water irrigation

- Landscape building and natural environment maintenance